- Home

- Companies

- Parson Environmental Products, Inc.

- Products

- Parson - Composite Liner System

Parson - Composite Liner System

Combines High Strength Mortar with a 100% solids Epoxy Corrosion Barrier in a same day application.

Advantages

- Cost–effective alternative to Polyurethane systems

- Restores structural integrity

- Provides highest level of corrosion protection

- Spincast or Spray Gun application

- Use on new or existing structures

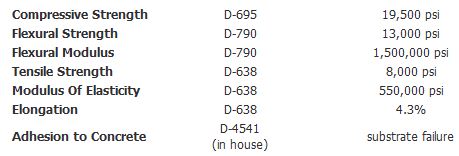

Physical Properties

MH Liner Cement Mortar Application

Thoroughly clean and remove any loose or foreign materials including paints, dirt, oil, grease, surface coatings, laitance and any other bond-inhibiting material from surface to be coated, using minimum 3500 psi waterblast. Stop all active leaks. (Please refer to our Manhole Rehabilitation Specifications for product selections.) Surface should be Saturated Surface Dry (SSD) just prior to material application. Any standing water must be removed.

Add approximately 3/4 gallon of potable water per bag of PARSON MH LINER. Apply using low pressure spray equipment or trowel to vertical, horizontal and overhead surfaces to a thickness of 1/2”. Trowel and brush as soon as possible, but within two hours. Do not apply to frozen surfaces.

Parsonpoxy SEL-80 Epoxy Application

PARSONPOXY SEL-80 is supplied as a two-component, pre measured kit. Mix Parts A & B separately for approximately 1 minute using a mechanical mixer. Pour the entire contents of Part B into Part A container and mix for approximately 3-4 minutes until thoroughly blended and a uniform color is achieved. Spray 80 mil top coat over MH LINER within 36 hours, using spray equipment approved by the coating manufacturer. Application temperature range is 40F and 100F.

Precautions

See MSDS for specific instructions. Use protective eye wear, cover exposed skin and use breathing protection.