Aqua-Pipe - Composite Material Woven Polyester Jackets

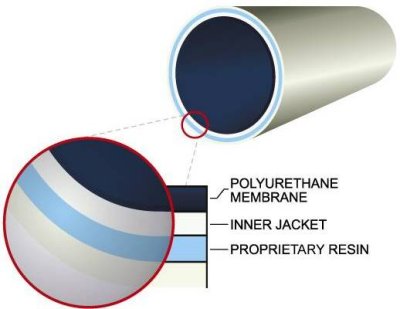

Aqua-Pipe is composite material i.e. woven polyester jackets (with a polymeric membrane bonded to the interior to ensure watertightness) and specific epoxy resin. It is available in 6 to 24 inch (150 to 600 mm) diameters for water main distribution systems.

Aqua-Pipe is designed and installed according to ASTM F 1216 and ASTM F 1743 Standards. It is designated as a Class IV fully structural liner when compared to the AWWA M28 structural classification. This means that Aqua-Pipe is a stand-alone structural liner that can withstand all dead and live loads and internal pressures, including a vacuum, without the help of the residual strength of the existing pipe. If the host pipe is depressurized, Aqua-Pipe will resist the external dead and live loads. Aqua-Pipe can withstand operating pressures up to 150 psi.

Aqua-Pipe is certified by NSF/ANSI Standard 61, UL, NQ 3660-950, and is a WRAS approved product (BS6920).

Aqua-Pipe is impregnated onsite with specific epoxy resin and is then pulled in place through the host pipe. The Aqua-Pipe liner is shaped by pushing a pig through the liner using water pressure and then cured with circulating hot water (CIPP).

The service connections are reinstated from within the pipe using a remote controlled mechanical robot. A closed-circuit television (CCTV) system is used to monitor the operation. Watertightness is preserved by the resin that surrounds the threaded cavities of the service connections and ensures a tight bond with Aqua-Pipe.

- Diameters: 6 to 24 inches (150 to 600 mm)

- Installation Length: Up to 1,000 feet (300 m) between access pits.

- Installation Method: Pulled-in-Place Piping (PIPP)

- Materials: Composite of woven textile jacket with epoxy and an inside polymeric membrane for watertightness

- Trenchless technology: Cured-in-Place-Piping (CIPP)

- Mechanical Properties: Exceeds ASTM F1216 and ASTM F1743 Standards

- Product Certification: Certified to NSF/ANSI Standard 61, WRAS

- Hazen-Williams Coefficient: Greater than 120

Certifications

- Aqua-Pipe is officially certified by NSF to NSF / ANSI Standard 61 - Drinking Water System Components. Aqua-Pipe is listed on the NSF website.

- Locate pipe

- Install temporary bypass through water meters or garden spigots

- Excavate access pits at each end of the pipe section

- Clean pipe with metal chain reamer

- Inspect pipe through closed-circuit television (CCTV) inspection to map the service connections

- Insert plug in every service connection from inside the pipe using specialized robotic equipment

- Inject epoxy into the liner onsite and pull liner into place

- Form the liner by sending swabs from one end to the other

- Circulate hot water for curing

- Perform hydrostatic pressure test

- Reinstate service connections by drilling with specialized robotic equipment from inside the pipe

- Disinfect pipe

- Reconnect water distribution systems

- Remove temporary bypass

- Restore site

Engineers now have more options:

- Possibility to line pipes that are difficult to access (underneath bridges, highways, etc)

- No future maintenance required

- Excavate access pits at each end of the section

- Future dry and pressure taps of service connections easily carried out

- Little excavation when compared to traditional open cut

- Possibility to line through bends

- Adjacent infrastructures not disturbed by work

- Less complaints from residents during work

Aqua-Pipe adds years of service life to water distribution systems by:

- Increasing pressure and flow capacity;

- Adding corrosion resistance;

- Regaining structural capacity.

Economic considerations are the key to success with Aqua-Pipe:

- Rehabilitation costs generally up to 30% less expensive than traditional open cut;

- Prevention of future water main breaks;

- Reduction in treatment and pumping costs;

- Elimination of further interventions on rehabilitated water mains;

- Reduction of social costs.

CIPP is used to rehabilitate existing water mains by lining the walls of the existing pipe with a hardened synthetic fiber tube. Hardening of the resin-soaked fiber tube is achieved using steam or hot water, depending on the specific manufacturer`s process.

The cleaning of the existing pipeline has to be completed prior to surveying the laterals. Once the liner is completely cured, the laterals are reconnected by cutting and reaming the liner with specialized robotic equipment.

There are also numerous benefits relating the use of this method:- Prevention of water main breaks

- Increased hydraulic carrying capacity in rehabilitated system

- Makes previously lost water available for sale

- Improved fire flow from hydrants, which can reduce insurance rates

- Reduced pumping costs

- Savings in the cost of energy to pump water

- Curtailing of coliform bacteria regrowth

- Savings in the cost of chemical treatment

- Stabilization of chlorine residuals

- Clean, clear water free of odor, poor color, unpleasant taste and turbidity

- Reduction in danger of undermined pavement

- Resistance to chemical attack

- Encasement of lead joints to reduce threat to water safety

- Substantial savings

- Pipeline can be rehabilitated while in place

- No loss of water supply for the rehabilitated area (minimal disruption of water supply via a temporary by-pass system)

- Minimal disruption of the area (services and traffic) since only small excavation pits are used to access the pipe

- Facilitates the overall cleanliness of the project, as opposed to the excavation of an entire road section

- Technique can be applied to pipeline material such as cast iron, steel asbestos cement or ductile iron

- Individual water services do not have to be excavated

- Due to trenchless installation, future deterioration of road bed and pavement are minimized