- Home

- Companies

- Particle Measuring Systems (PMS)

- Products

- PMS - Model NanoAir 10 - Condensation ...

PMS - Model NanoAir 10 -Condensation Particle Counter (CPC)

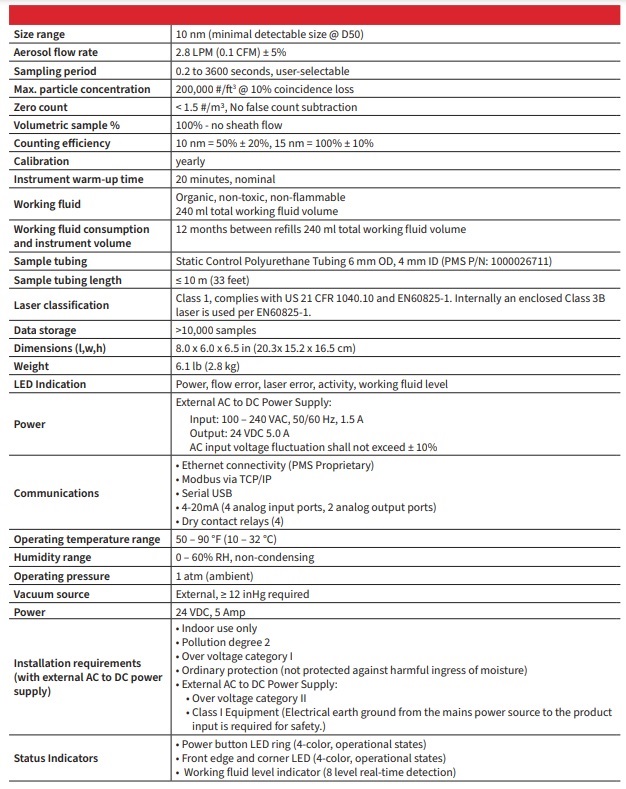

10 nm CPC sensitivity with the ease of use of a traditional particle counter. Purpose-built 10 nm condensation particle counter designed for use in the most critical fab spaces. The NanoAir 10 Condensation Particle Counter (CPC) is a revolutionary new product from Particle Measuring Systems (PMS). It provides the sensitivity of a CPC with the ease of use and functionality of a traditional cleanroom particle counter. Designed to monitor ultra-clean environments, it delivers 10 nm detection sensitivity at a sample flow rate of 2.8 L/min (0.1 CFM).

The NanoAir 10’s size is 83% smaller than competitive condensation particle counters making it practical to use anywhere in ultra-clean environments, including inside semiconductor process tools and equipment front-end modules (EFEM). The innovative patent-pending working fluid handling system design is robust and efficient, enabling 24/7, 365 days continuous operation without the need for maintenance or user intervention of any kind between the annually required working fluid refill and calibration. Thereby, reducing sampling and data collection interruptions and tool downtime.

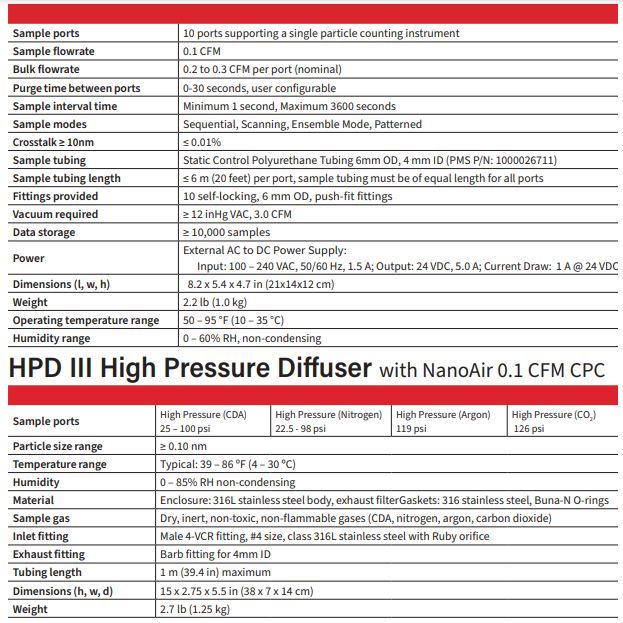

A 10-port manifold companion product (ParticleSeeker™) supports applications that require multiple sample locations to be monitored in sequential or programmed sequences.

Additionally, the NanoAir condensation particle counter is high-pressure gas compatible with the HPD-III from PMS, and data can be viewed, analyzed, and reported using PMS Facility Net facility monitoring software or transmitted directly to third-party SCADA systems or process tool inputs.

Particle Measuring Systems engineers, manufactures, installs, calibrates, repairs, and maintains the NanoAir™ 10 Condensation Particle Counter, and ParticleSeekerTM Multiport Aerosol Sampler Installation, Repair & Maintenance Services.

- The small form factor (16.5 x 20.2 x 15.2 cm) sets the standard for CPC’s designed for manufacturing and process control applications

- External volumetric size is over 80% smaller than the next smallest industrial CPC allows monitoring:

- within process tools in the most critical functional areas

- on congested high-pressure gas distribution utility pads

- Patent-pending, innovative, working fluidics design allows for 24x7x365 days operation without working fluid maintenance; thus avoiding any sampling and data collection interruptions

- Refills only 1x per year at annual calibration, capable of 15 months between refills with 24x7

- full-time operation

- No potential for unwanted fluid migration during shipping, handling, and installation that is

- common in other industrial-application CPCs

- Ready for operation in under 20 minutes after connecting vacuum and power

- No internal pumps or fans, eliminating maintenance and potential particle generation

- Sample flow rate of 2.8 LPM and does not use sheath airflow, providing volumetric sampling

- capability

- Zero Count is < 1.5 counts/m3 without the use of zero count subtraction schemes

- Results in best-in-class performance and enables use in ISO Class 1 environments

- Only aerosol particle manifold on the market designed and purpose-built to handle particles

- down to < 10 nm

- 10 manifold points providing 120 m2 of fab/process space sampling coverage. Each sample

- tube can be up to 6 m in length

- Multiple modes of manifold Sampling:

- User Defined Sequence

- Ensemble samples all ports simultaneously

- Sync (via Dry Contact Relay) communicates with external fab processes in real-time to

- synchronize with events and follow movement within the environment

- Effectively eliminates crosstalk and other common nanoparticle transport handling problems

- The utilities interface “Base Station” retains all local configuration (Location, IP address, recipe settings) at the point of installation, allowing the ability to swap NanoAir and ParticleSeeker instruments, eliminating re-configuration downtime.

- Multiple Input/Output communication interfaces enable seamless SCADA data transfer, reducing process tool downtime

- Dry Contact Relay (x4) for selecting and synchronizing sequence modes (ensemble mode, user defined sequence, wafer flow path)

- 4-20mA analog inputs (x4) for additional sensors, such as Temperature, Relative Humidity, and Differential Air Pressure

- 4-20mA outputs (x2) for single channel particle data export to data handling and SCADA

- USB for Serial (service port)

- USB for flash memory

- Ethernet ports (2):

- PMS Ethernet Protocol for FacilityNet Software communication

- MODBUS over TCP/IP communication with process tools and other fab system interface

- DC Power ports (x2) allows a ParticleSeeker to share power with a NanoAir

- Vacuum port for house or external source (>12 inHg)