- Home

- Companies

- Conifer Systems

- Products

- Conifer Systems - Model CATOX - ...

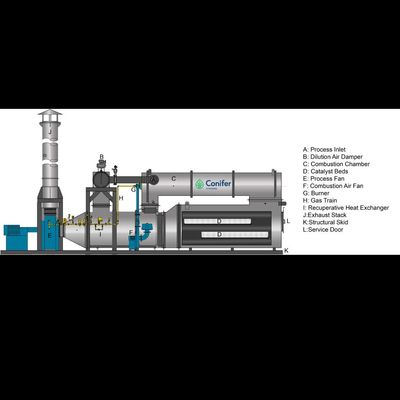

Conifer Systems - Model CATOX -Catalytic Oxidizer

Catalytic oxidation is a common method of volatile organic compound (VOC) removal. This chemical process raises the exhaust stream temperature to a preheat temperature before moving through its first bed of catalyst. The catalyst increases the rate of the oxidation reaction and the chemical bonds that hold the volatile organic molecules together are broken. The VOCs in the process exhaust stream are converted to carbon dioxide, water, and thermal energy by the catalyst and temperature of the combustion chamber. Oxygen deficient process streams may require dilution with additional air to ensure enough oxygen is present for complete oxidation.

The process of regenerative catalytic oxidation operates with two heat recovery canisters, which contain a ceramic heat recovery media. The media acts as a heat exchanger for the system and the two canisters operate under a “swing bed” absorption principle known as flow reversal. Using this principle with ceramic stoneware, results in a process called regeneration.

As the process exhaust stream travels through the first media bed, it adsorbs heat energy stored in the ceramic media mass, which pre-heats the exhaust stream. The exhaust stream then enters the catalyst bed where it begins to oxidize before entering the combustion chamber. Here, additional heat energy is added from the burner to reach the required system operating temperature. After the temperature has been elevated and retained, the process gas moves through a second catalyst bed, completing the destruction of the VOC. Now, the clean exhaust stream passes through the second heat recovery canister. Here, the cold ceramic media mass absorbs the heat from the exhaust stream and stores it for the reverse flow of the system. Once the heat energy of the first canister has been depleted through the absorption into the incoming air stream, the flow through the system is rotated, so that the incoming cold, dirty air is directed through the second energy recovery canister, with the hot, clean air now exiting through the first recovery canister.

In a unit with three canisters the same principle applies but now there are now three different cycles available. The canister not part of a regeneration cycle is getting purged. This prevents untreaded VOCs from being pushed out of the system during the cycle switching process and thereby allows for a greater achievable overall destruction efficiency.

By using the reversal of exhaust flow through the ceramic beds, a minimal amount of axillary heat energy needs to be added to the exhaust stream. The sizing of the ceramic media beds is such that a peak of 95% mass corrected heat recovery efficiency is possible through the regenerating, reversal flow process.