- Home

- Companies

- Conifer Systems

- Products

- Conifer Systems - Model Scrubber - ...

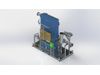

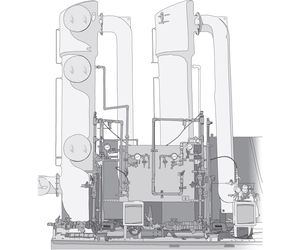

Conifer Systems - Model Scrubber -Scrubbers

Scrubbers remove dangerous particles from industrial gas streams without burning or using fuel. Scrubbers are ideal for applications that require high temperatures, highly acidic exhaust streams, or harsh chemicals.

A wet scrubber, or wet scrubber system, is a type of pollution control equipment that is designed to remove harmful gases and particulates from industrial exhaust streams. It works by funneling the exhaust stream through the bottom of a packed tower and then it passes through randomly dispersed packing to improve contact between the gas and liquid phases. A solution from specialized nozzles is sprayed countercurrent to the exhaust stream flow. This solution can often be water, especially when the stream is primarily dust or dust like particles.

When the waste gas has lower solubility, chemicals are usually added to the solution. These chemicals react with the compounds released in the exhaust stream, which are generally acidic gases. After the exhaust stream is treated, the gases are released, clear of the dangerous gases and / or particles. The cleaned gas then passes through a mist eliminator to remove any entrained liquids. The clean air is then released into the atmosphere.

The Scrubber system shall be designed for the removal of the ammonia vapors from off gas. A header with spray nozzles delivers the recirculation solution through the top of the scrubber tower. The process gas flows vertically through randomly dispersed packing designed to improve contact between the gas and liquid phases. The Scrubber system utilizes a specialized chemical solution as the scrubbing agent. In certain cases, other contaminants which are low in solubility require the addition of chemical additives to improve absorption.

A pH Analyzer/Transmitter shall constantly monitor the recirculating solution pH to ensure it’s adequate to neutralize the absorbed chemicals. It is expected that the pollutant removal will generate a quantity of effluent blowdown which will reach its maximum during peak loading into the system. Blowdown shall be achieved through exhaust side of the recirculation pump and be controlled by a solenoid valve. Liquid level switches installed on the sump pump measures the blowdown.

A mist eliminator section at the top of the scrubber tower knocks down entrained water droplets before the clean air exhausts to atmosphere. The scrubber exhaust discharges through the outlet nozzle and is directed to the process fan through induced draft action, and finally to the exhaust stack.