- Home

- Companies

- Devise Engineering S.A.

- Products

- Devise - Model CSDP - Containerized ...

Devise - Model CSDP -Containerized Sludge Dewatering Plants

The proposed Containerized Sludge Dewatering Plants by DEVISE present a complete solution for the management (thickening & dewatering) of primary and biological sludge produced during municipal or industrial wastewater treatment. All the necessary systems & equipment for the dewatering plant, excluding the sludge collection tank-basin, are pre-engineered, pre-fabricated, hydraulically & electrically connected and installed inside a standard ISO Container (20 ft or 40 ft). The size of the container depends on the plant capacity. This container serves as housing for the necessary systems & equipment and therefore comes complete with lighting, internal wiring, water supply, thermal insulation and air extraction. The plant may also be supplied with its own “odor control” unit.

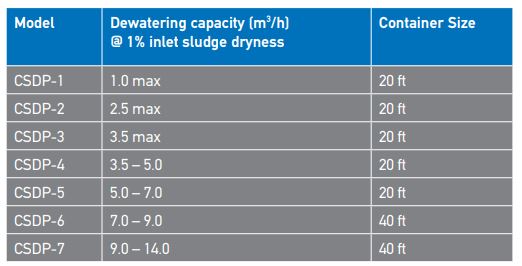

The Containerized Sludge Dewatering Plant uses for its basic function a top quality centrifuge decanter and can achieve de-watered sludge cake between 18-25% dry solids concentration. The standard models offered are shown below:

The Containerized Sludge Dewatering Plant (CSDP) generally consists of the following systems & equipment:

- Sludge Feed Pump(s) of the progressive cavity type

- Sludge Flocculator of the dynamic type (tank & mixer)

- Polymer solution preparation unit of 2 or 3 chambers (supplied in a semi-automatic or fully automatic type]

- Polymer solution dosing pump(s]

- Sludge dewatering unit of the decanter centrifuge type

- Inclined screw conveyor for lifting & disposing of the dewatered sludge cake to appropriate container(s)

- Wash-water system for the plant`s cleaning requirements

- Equipment piping and wiring

- Air extraction is standard and odor control comes as optional

- Fully automated Local Motor Control Center with PLC

- Fully furnished housing with lighting, thermal insulation and other building services of high standards

- Compact design

- Pre-engineered & prefabricated system

- Easily transportable ISO container package

- Ready to plug & play

- Suitable for decentralized STPs and industrial effluent treatment applications

- All-inclusive systems with autonomous PLC electrical panels

- Cost effective method of sludge dewatering for small to medium size WWTPs

- On site sludge management without need for civil works or buildings