- Home

- Companies

- Smiley Monroe Ltd

- Products

- Smiley Monroe - Model Toughflex - ...

Smiley Monroe - Model Toughflex -Conveyor Belt

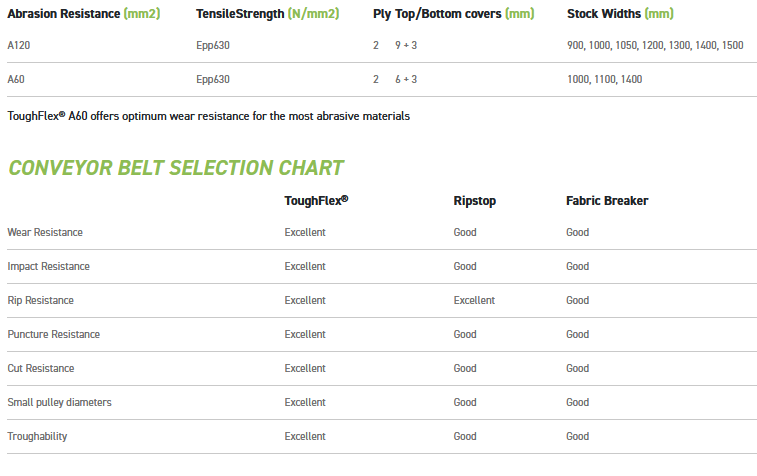

Our ToughFlex range is the perfect all-round solution for extreme conveying. In many applications such as primary and secondary crushing, even the thickest and heaviest conventional belts can be torn or ripped by large, sharp, and heavy materials such as construction and demolition waste or unprocessed aggregates falling onto the belt or becoming stuck. Such damage can wear down belts within a relatively short time, leading to unwelcome downtime and costly replacement belts.

Lasting up to four times longer than standard EP Multiply belts ToughFlex®’ is based on a straightwarp construction with a special weave of 2 fabric plies and an additional binder warp. The plies are reinforced to resist puncturing and are protected by premium, wear-resistant top and bottom covers.

Now available In a range of belt thicknesses, ToughFlex® can be utilized as a premium belting across the whole machine from primary/ main conveyors to side conveyors. The belt of choice by several prestigious OEM brands, ToughFlex® belts are working around the world in a range of applications from road planing, crushing, screening and construction waste recycling.

- Superior cut, impact and wear-resistant covers

- Reinforced plies to resist puncturing

- Performs well on small to medium-sized pulleys

- Excellent troughability

- lasts up to four times longer than standard EP multi-ply belts.

- Can be easily recycled

ToughFlex® belts can be found the world over, in the harshest conveying applications from primary crushing to C&D waste recycling and road construction.