BAC - Model DFCV-AD -Cooler

Pads in front of the finned coil pre-cool air to virtual wet bulb temperature. Up to 40% improved capacity compared to dry cooling. TrilliumSeries coolers consume less energy. TrilliumSeries coolers achieve low process temperatures. Try the cooler with EC motor and improved pre-cooler performance resulting in lower sound levels and 25% lower electrical consumption.

Saving water

- TrilliumSeries coolers achieve annual water savings exceeding 80% water compared to normal cooling towers by limited adiabatic operation.

Top hygiene control

- Featuring a once-through system: recirculation and stagnation of water eliminated.

- No stagnant water: pre-cooler water conveyed from pads to sewer via a gutter.

- No aerosol formation: TrilliumSeries Coolers minimize the Legionella risk.

- TrilliumSeries Coolers cool incoming air without transferring water to the dry coil

- Boosting thermal performance

- Saving water

- Top hygiene control

- Small to medium HVAC and industrial applications

- Locations with limited water and space availability

- High temperature industrial applications

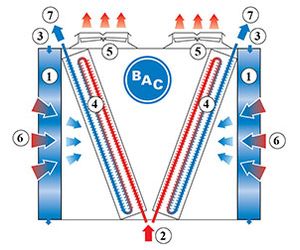

The DFCV-AD is a V-shaped dry cooler equipped with adiabatic pre-coolers (1) that cool the warm process fluid (2) by sensible heat transfer. Water flows (3) evenly over evaporative cooling pads located in front of the dry finned coil (4). At the same time axial (5) fans draw air (6) through the pads where a portion of the water evaporates and cools down the saturated air. This increases the cooling capacity of the incoming air for cooling the process fluid (7) inside the coil.

Material options

- Heavy-gauge hot-dip galvanized steel is used for unit steel panels and structural elements featuring a zinc aluminium coating.

Heat transfer media

- The V-shaped finned coil is constructed of staggered and seamless copper tubes (15,9 or 12,7 diameter) with aluminium, rippled and corrugated fins.

- 2,5 mm fin spacing for optimal air turbulence

- Thick and seamless copper headers and threaded steel connections

- Pressure tested at 15 bar

- Try our option for aggressive environments: special pre-coated anti-corrosion aluminium fins.

- Axial fan with exceptionally compact direct drive short integrated motor and fan guard.

- The low profile fan with fan guard features an impeller and motor and is balanced as a complete unit using dynamic single plane balancing. Balance grade is G6.3.

- Fan and motor totally maintenance free, and allow frequent starting.

- Bearings seals and motor encapsulation for long service life.

- The adiabatic units fitted with EC motors (EC in model number) provide an immense reduction in power consumption. The fans are piloted over an RS485 bus system by the controller supplied together with the electrical panel.

Principle of operation: the magnetic field of the permanent magnets in the outside rotor is used by the consecutively powered windings in the inside stator to let the fan run. The Hall-sensor detects where the magnetic field is strongest, which determines which set of windings will be activated.

Adiabatic pre-cooler

- Evaporative cooling pad of impregnated cellulose with different flute angles encased in bolted heavy gauge stainless steel.

- Distribution pad on top for complete pad wetting.

- Once-through water distribution system, no need for pumps, water drained to sewage.

Electrical panel and adiabatic controls

- Fully equipped factory-installed electrical panel with integrated motor controls and adiabatic controls as well as all the required circuit breakers and other auxiliary components.

- Units with regular AC have an electrical panel which additionally contains a variable frequency drive.