- Home

- Companies

- Merus GmbH

- Products

- Cooling Water Systems

Cooling Water Systems

Saudi Aramco is a government owned company and not only known as the world largest producer of oil, but also as the world most valuable company. Also it is common knowledge, Saudi Aramco has the most proven production of oil and oil reserves in the world. With almost 60000 employees Aramco produces out of more then 250 oil and gas fields. Next to the production and transportation of the Oil and Gas, Saudi Aramco operates also a row of refineries, where Riyadh Refinery is one of them. The refinery was commissioned in 1981 and is producing more then 100KBD. The cooling water system has central cooling towers, feeds with a several kilometer long piping network almost 300 heat exchanger and different machines. The total amount of water in the system is around 5.500 m3, the feed water has app. 2000 TDS, the blow down around 5000 TDS.

The first trail with the MAERUS Rings have been done at a few, most critical Heat Exchanger, where there was a possibility to open and check the results during regular operation.

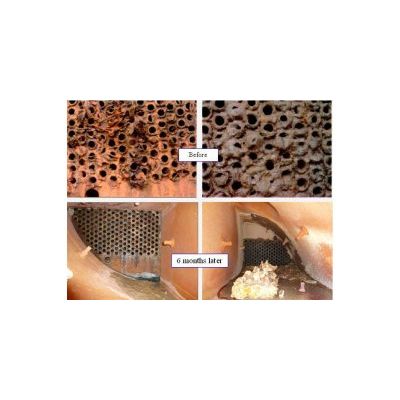

Tubular Heat Exchanger before and after installation of MerusThe 2 pictures on the top (marked as before) show how normally the inlets of the heat exchanger tubes are looking. Next to scale, corrosion and mud artificial particles are found as well.

When taking the pictures there was no mechanical cleaning done, just taken a picture and closed the heat exchanger again, in order to see if Merus is able to remove the existing fouling.

The 2 pictures at the bottom showing an outlet and an inlet of each one pass of this 6path heat exchanger. The surfaces after 6 month using MERUS has been totally clean, no scale, no fouling or any trace of corrosion could be found. On the lower right side the sludge which can be seen is originated from the sacrificial anode.

After seeing the results of the MERUS treated Heat Exchanger the trail was broadened and installation took place at another 50 Heat Exchanger, in order to verify the seen results during the regular shut down of the refinery. During the shutdown of the refinery, next to all Heat Exchangers has been opened and cleaned. It was very obvious; the MERUS treated Exchangers have been either totally clean or far cleaner than the untreated one

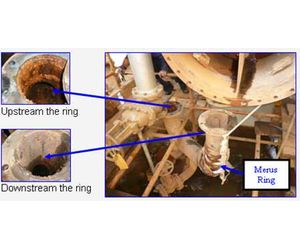

On the U-bend the MERUS Ring is installed. To confirm the effect of MERUS pictures where taken, both upstream and downstream the position of the ring. As MERUS is working only downstream, it can be seen the untreated pipe still has fouling and scale whereas downstream the rings all scale is gone.

Here two inlets to a heat exchanger can be seen, as well one from upstream and one from downstream the point of installation. The picture to the right shows the header of a heat exchanger, when it was dropped on a truck. This was done to move the header to the cleaning of the heat exchanger, which has taken place not inside the refinery but a dedicated cleaning place.

When dropped, all the scale and fouling just fall to the bottom on the truck. No scale sticking to the surfaces, no corrosion found. The cleaning of the Heat Exchangers which has been treated has been very easy, no need of aggressive chemicals, in most cases the mud and debris could be removed just by using a normal water hose or a regular pressure cleaner.After the shut down there are discussed several ways forward. The ultimate goal would be to control the entire cooling system. What to expect and how to achieve this, is described below.

The whole project is divided in 4 phases, only if one phase is realized, documented and approved, the next phase will start. The whole project will run over 3 years, and only at the end it can be decided, if it is possible, with the results seen, for instance to extent the service cycles for the heat exchangers on the water side.