- Home

- Companies

- Stokkermill | Seltek Srl

- Products

- Stokkermill - Model Compact - Copper ...

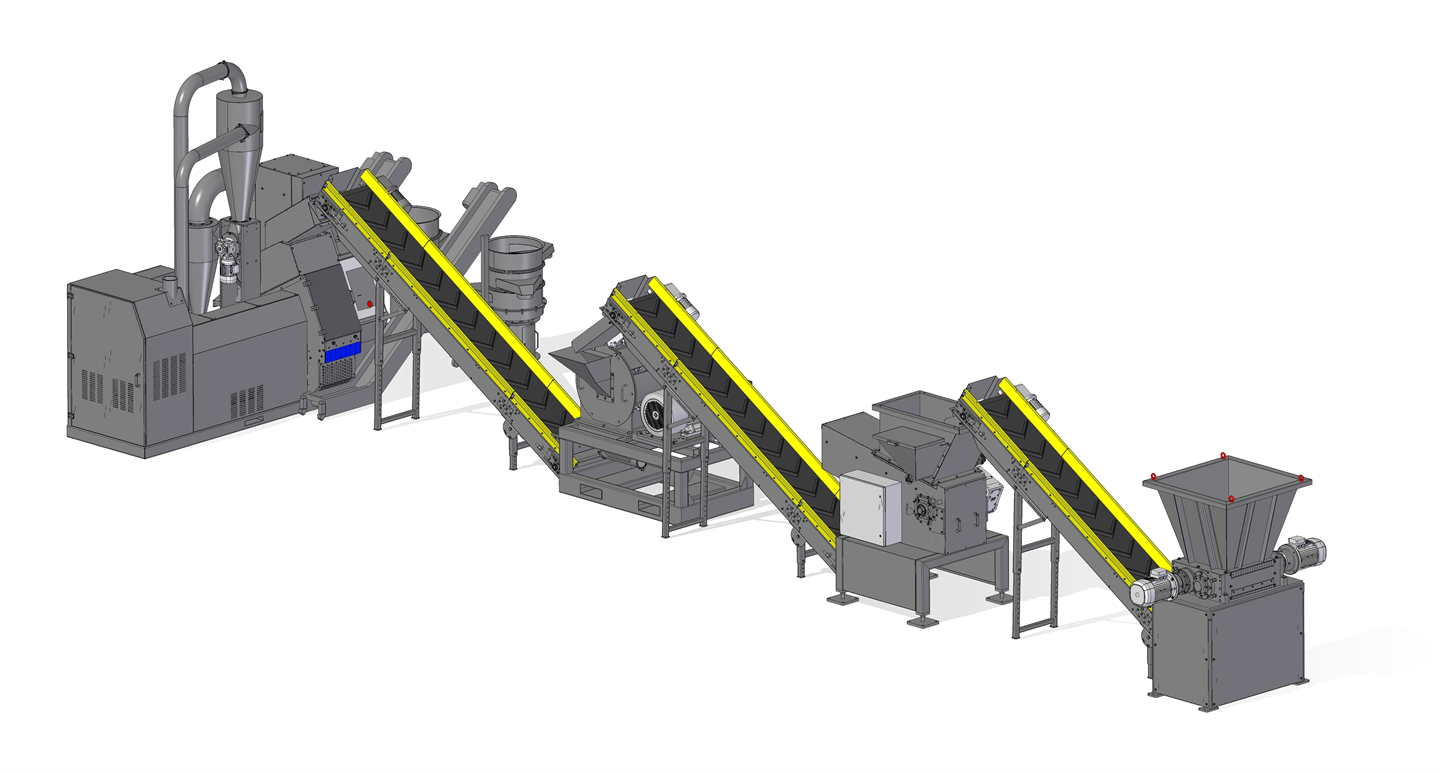

Stokkermill - Model Compact -Copper Wire Granulator

COMPACT wire cable granulators are chopping machines designed for milling the copper or aluminum cables and sorting the metal from the insulation. COMPACT are available in 5 models with input rates ranging from 100 to 1000 kg/h input. Properly sized drive motors permit to overcome unpredictable load allowing stable operation and low energy consumption. COMPACT wire chopper machines are equipped with the ML blades mill manufactured from a unique steel block without weldings and available in different configurations with 3 or 5 rotating blades and 2 or 4 reversible fixed blades.

COMPACT does not require any water cooling thanks to the correct size of all the process components like the transport pipes, the cyclones and the filtration systems.

COMPACT wire cable granulators are designed to be easily equipped with a TURBO device as second refining step for increasing the production capacity rate. COMPACT can be put in line with the PS shreddings by a NST conveyor belt.

COMPACT series granulators are suitable for processing:

- copper and aluminum cables

- thin cables (i.e., data and telephonic cables, e-waste harness) by using a smaller classifier screen

- pre-shredded copper-aluminum coils and radiators

Power

9.5 kW

Dimensions

1060x1700x2000 mm

Weight (kg)

800 Kg

Production Input kg/h

80-100 / 80-120 Kg/h

Power:

14 kW

Overall dimensions:

1500 x 1700 x 2080 mm

Weight:

1000 Kg

Input production:

100 - 150 Kg/h

Power:

20 kW

Overall dimensions:

1500 x 1700 x 2130 mm

Weight:

1200 Kg

Input production:

200 - 250 Kg/h

Power:

36 Kw

Overall dimensions:

4200x1750x3440 mm

Weight:

2200 Kg

Input production:

170 - 250 Kg/h

Power:

49 Kw

Overall dimensions:

4200x1750x3440 mm

Weight:

2500 Kg

Input production:

250 - 350 Kg/h

Entry Line - Granulator with Pre-Shredder

The plants for the treatment of copper and aluminum cables and radiators of the Entryline series allow to treat medium quantities of material, obtaining an exceptional quality of the output product and the same technical and constructive excellence of superior capacity models.

They are intended for all professional operators who are looking for equipment that is not too expensive but of high quality, to solve the needs of a discontinuous market such as the current one, allowing a quick return on investment.

Entryline lines can be implemented with optional equipment to increase their production capacity when customer needs increase.