Welding Alloys

Hardface - Model HC-O -Cored Wire for Severe Abrasive Wear Applications

FromWelding Alloys

HARDFACE HC-O is a specialized cored wire designed for self-shielded metal arc hardfacing processes. It delivers a high chromium cast iron deposit with a significant quantity of hard primary chromium carbides embedded in a resilient austenitic matrix. This composition makes it exceptionally suitable for components exposed to extremely severe abrasive wear combined with moderate impact. The wire is engineered to enhance durability and performance in critical applications, ensuring extended service life of wear-intensive parts. It is important to note that welding techniques and product specifications are subject to modifications, and users must evaluate the product's appropriateness for their specific needs and applications. The product details provided are intended as general guidance and may vary by region; consulting local subsidiaries is recommended for accurate information.Most popular related searches

Alloy Type: Anti-Abrasion

Hardness: 58 - 64 HRC (As welded, 3-layers)

Cracks: Yes

Machinable: No

Multi-layer: Yes

EN ISO Classification(s): EN 14700: T Fe15

Welding Process(es): FCAW-S

- High chromium cast iron deposit containing a high proportion of hard primary chromium carbides in a tough austenitic matrix

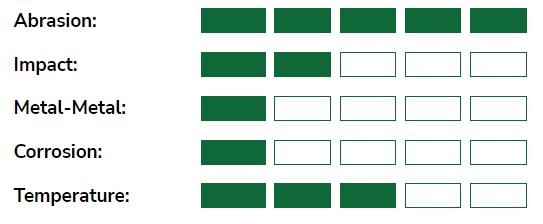

- The deposit is suitable for hardfacing components subject to extremely severe abrasive wear and moderate impact