- Home

- Companies

- Coulson Ice Blast

- Products

- Coulson Ice Blast - IceStorm90 - ...

Coulson Ice Blast - IceStorm90 - Professional Alternative to Dry Ice Blasting

The IceStorm90 is an innovative and effective industrial cleaning technology utilizing wet ice (regular ice cubes) as a cleaning media. By utilizing the superior cleaning power of wet ice, not only is the technology much more cost effective to operate, it is also safer and makes waster containment easier. The IceStorm90 works by crushing ice cubes which are then fed into a high pressure airstream and blasted at high speed from a nozzle aimed at the surface to be cleaned. Ice can be made practically for free using standard ice cube machines or freezers or it can be purchased from an international network of partnered ice cube suppliers, who will deliver ice right to where you need it.

- Simple operating controls

- Superior internal ice crusher, capable of accepting wide range of ice shapes and sizes

- Non-pressurized hopper, large enough to hold 90 lbs of ice (ice is fed from hopper into high pressure airstream with engineered rotary feeder)

- 110 V electrical plug

- Weight: 400 lbs

- Compact: 40”x26”x45” (LxWxH)

- Operating Pressure:

- 80 PSI – 150 PSI

- 180 CFM – 425 CFM

- Variable feed rate: 0 – 5 lbs per minute

- PSI gauges measure pressure in and out

- Anodized exterior panels

- Stainless steel option available

- 36 month warranty

- Low levels of airborne contaminates during blasting

- Finely tuned to increase life cycle and efficiency.

IceStorm is sold complete with one length of ice hose, one length of air hose, and one blast trigger with removable nozzle.

- Surface Prep

- Automotive

- Deburring

- Foundry

- Tire Molds

- Petrochemical

- Graffiti Removal

- Nuclear

- Asbestos

- Asphalt Removal

- General Maintenance

- Cleaning Contractors

- Food Processing

- Pulp & Paper

Superior Cleaning Power

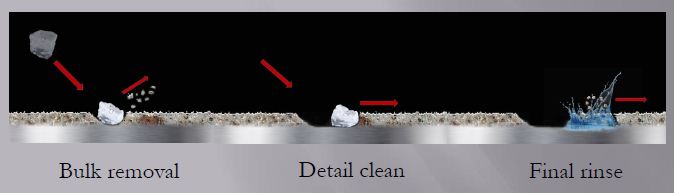

Ice has a superior cleaning power to many other forms of media and is the only medium to use all three states of matter during blasting; solid state to hit with maximum impact for bulk removal, liquid state to trap and contain airborne contaminants, and gaseous state to minimize waste streams and provide the final rinse.

Cost-Effective - Minimal Media, Capital & Lower Operational Cost

Ice is the lowest media cost and can last forever if stored correctly. This helps you reduce both media costs and operational costs. Additionally, it saves you from supply shortages (as frequently happen with dry ice) or rapid increases in media cost.

Environmentally Friendly - Minimal Waste & Contaminants

Ice is environmentally friendly with minimal levels of airborne contaminants (0.003 MG/m3), less water requirement (up to 95%), and minimal residual water waste. It releases no greenhouse gases (compared to 259,200 lbs. for dry ice blasting*) and only needs minimal ground containment (compared to full containment*). This will help you to meet the more stringent environmental regulations enacted since the development of traditional blasting.

Health Risk Elimination

No chemicals or airborne contaminants are required throughout the cleaning process, which eliminates worker health risks and increases overall operational safety.

Time Saving - Unique Cleaning Mechanism

Ice is the only medium with three cleaning mechanisms (bulk removal, detail clean, and final rinse). You can decontaminate and clean in one step rather than two steps for traditional dry ice blasting.