- Home

- Companies

- Cross Wrap Oy

- Products

- Cross Wrap - Fully Automatic Direct ...

Cross Wrap - Fully Automatic Direct Bale Wrapper

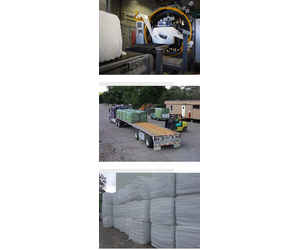

Cross Wrap fully automatic bale wrappers provide industry-leading protection for all material bales and recyclables. The CW Direct Bale Wrapper wraps each bale without the use of bale wires while also boosting production rates and enhancing workplace safety. Cross Wrap bale wrappers are compatible with all bale sizes and production capacities, and they offer an industry-leading 80-tonne-per-hour capacity. They work especially well with RDF and SRF. The CW Direct Bale Wrapper provides smarter and dependable bale handling, shipping, and storage.

Many two-ram baler brands across 55 countries rely on Cross Wrap’s unique bale wrapping technology, and Cross Wrap has delivered more than 500 bale wrappers worldwide. Cross Wrap bale wrappers also help to optimize film consumption. Whatever you need to wrap, ship, or store, Cross Wrap can help you choose the wrapping solution that’s best for your specific needs.

The CW Direct Bale Wrapper wraps bales directly from any two-ram baler chamber. This simplifies and shortens the wrapping line and keeps the working environment litter-free with minimum bale conveying. The CW Direct Bale Wrapper can also be equipped with a separate wire or strap tying unit that enables the production line to work flexibly with different baled materials. The operator has the ability to bale and tie or bale and wrap the material, a feature that is only possible with the CW Direct Bale Wrapper.

Cross Wrap bale wrappers offer the highest production rate and lowest operational cost in the industry. And Cross Wrapping bales is the most environmentally safe solution for demanding transportation and storage needs because it protects the materials inside the bale and minimizes damage, leakage, and littering. Wrapped square bales save storage space and transportation space versus transporting loose materials and round bales. Cross Wrap machines have also proved to be cost-effective when utilized in smaller capacities.

Cross Wrap’s modular design system offers a flexible, space-saving layout solution for all production environments. Cross Wrap bale wrappers also offer helpful options that increase productivity, including in-feed, out-feed, and cleaning conveyors, opening safety fencing, weighing, automatic labelling, RFID, and remote access control. And Cross Wrap Direct bale wrappers use 750 mm-wide film. Plus, Cross Wrap bale wrappers are equipped with a Tosibox online modem (wifi, ethernet, or USB mobile connectivity) that allows remote troubleshooting and software upgrades, ensuring that your Cross Wrap bale wrappers will always perform at their best.

Cross Wrap bale wrappers are built to last and perform. The bale wrapping machines are engineered based on Cross Wrap’s patented innovation, it’s unique “all sides covered” bale wrapping method. This advanced bale wrapping method offers our customers a number of advantages: Cross Wrap Bale Wrappers can wrap any material bales and recyclables. CW Bale Wrappers are compatible with all baler machines and with all bale sizes and capacities. The CW bale wrapping method is a proven solution even with the most demanding waste materials such as MSW, RDF, and SRF. Today, CW Bale Wrappers are engineered to be compatible with over 23 different baler brands globally. That’s why we say, Cross Wrap knows your baler the best.

Cross Wrap provides high bale durability and smarter, more reliable handling, shipping, and storage. Cross Wrap’s unique bale wrapping method is relied on in more than 60 countries. Cross Wrap works with all of the baler brands. Cross Wrap has delivered hundreds of bale wrappers worldwide, wrapping a wide variety of waste and reject materials. With Cross Wrap, it’s easy to optimize film consumption, and customers can choose the wrapping solution that’s most suitable for their specific needs.

Solution for every balerCross Wrap Direct Bale Wrappers wrap the bales without the use of bale wires, saving time and money while simplifying the bale structure, improving efficiency, and enhancing workplace safety. Cross Wrap bale wrappers are fully automatic, saving labor costs and improving working safety. Cross Wrap bale wrappers work seamlessly with all baler brands and waste baler machines and they offer an impressive 80-ton-per-hour capacity. Cross Wrap machines are also economical when utilized in smaller capacities.

Safe and soundCross Wrapped bales are an environmentally safe solution for demanding transportation and storage needs, minimizing litter and protecting the materials inside the bale. Wrapped square bales save storage space and transportation space versus loose material and round bales. Cross Wrap’s modular design system, complete with various conveyor and component options, offers a flexible, space-saving layout for everything from small operations to the most demanding production environments.

Industry-standardCross Wrap CW 2200 Bale Wrappers offer the lowest operational cost and highest production rate in the industry. Plus they have an advanced bale conveying technique that uses belt conveyors instead of roll conveyors. This gentle bale moving method maintains bale shape and tightness the best way possible, minimizing bale breakage and litter.

Options that increase productivityCross Wrap bale wrappers can be run with both 500 mm- or 750 mm-wide films, depending on the customer’s needs. And there are additional options that increase productivity, including cleaning conveyors, opening safety fencing, weighing, automatic labeling, RFID, and remote control. All Cross Wrap bale wrappers are equipped with a 3G, LAN, WLAN modem that allows remote troubleshooting and software changes, ensuring that your bale wrapper always performs at its best.