- Home

- Companies

- Dynapower Company, LLC.

- Products

- Dynapower - Custom SCR Rectifiers

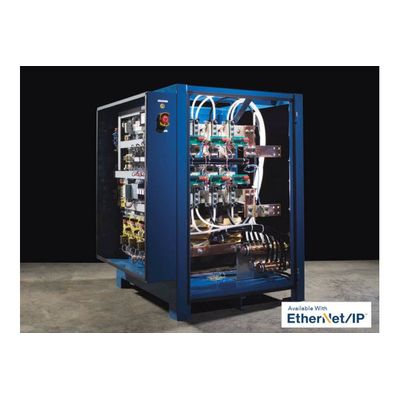

Dynapower - Custom SCR Rectifiers

Dynapower offers a full line of air and water-cooled custom SCR rectifiers to meet all of your needs. We have extensive experience in providing custom SCR rectifiers for a wide variety of applications that include metal finishing, anodizing, water treatment, crane duty, electrochemical applications, metal and battery formation.

There are also many different reasons to go custom. The most common is to power a very specific process. Here are a few common other ones we see.

- Your plant could have specific safety requirements that call for custom rectifiers (the most common)

- You may require high-voltage rectifiers or rectifiers that have very high arc flash potential due to the amount of power that they’re converting—which calls for custom additions so preventative maintenance can be performed on the machines.

- Larger, high-power rectifiers often tend to be custom engineered

- High precision processes or high volume with next to no downtime tend to be custom and require additional resiliency

When considering a high arc flash potential, a common custom feature would be a custom designed preventative maintenance port or a special layout so your access cabinets mitigate risk to maintenance personnel. Additionally it’s important to highlight that all of our rectifiers are designed around mitigating any inherent safety risks and to the highest safety standards.

Basically, the higher the quality standards become—whether through national standards or internal requirements—the more precise our customer base needs to be ensure there’s data connectivity between the unit. For instance, if you’re in a facility that needs to run three verifications of the part one layer of measurement, we could build you a custom rectifier with three points of measurement.

Dynapower’s rectifiers ensure years of maintenance-free operation and a long operating lifetime with the most comprehensive warranty in the industry. Here are some features to consider:

- Available in water-cooled or air-cooled designs

- Deep hole drilled silver plated copper bus bar

- Sealed enclosure for operation in aggressive environments

- Various NEMA ratings are available to meet the protection rating best suited for your application

- Protocol compatibility with Profinet or Ethernet/IP, etc

- Control upgrades to accommodate any process including touchpad controllers, touchscreen controllers, analog controls and anodizing controllers

- Input Voltage : Any voltage up to 6000 VAC, three phase 60 or 50 HZ. Other voltages and frequencies available upon request.

- Output Current: : Up to 50,000 ADC. Higher current available upon request.

- Output Voltage : Up to 1,000 VDC. Higher voltages available upon request.

- Cooling : Air, direct water, oil or closed loop.

- Magnetics : Low loss grain oriented silicon steel cores, all copper conductors, 220°C insulation and design temperature rise <80°C.

- Duty Cycle : All Dynapower rectifiers are rated for 100% duty cycle continuous at up to 40°C ambient. Higher temperatures available upon request.

- Precision Electronic Controls: In protective, sealed enclosures, isolating them from aggressive atmospheres.

- Automatic Voltage Stabilization: Maintains the output voltage constant to within ±0.5% of rated voltage from 0-100% of rated current.

- Current Limiting: Prevents the output current from exceeding a factory preset limit.

- Voltage Limiting: Prevents the output voltage from exceeding a factory preset limit.

- Peak Current Overload Detector: The PCOD continuously monitors the DC output for short circuit conditions. In the event of a short circuit, the PCOD reduces the output to a safe level, protecting the power supply from potentially harming overload conditions.

- Thermal Detectors: Strategically placed thermal detectors sense device temperatures and protect semiconductors and transformers.

- Remote Control: Remote control consoles include start-stop push buttons, a power-on light, analog or digital displays and control potentiometers.

- SCR Watchdog: A Dynapower exclusive, the SCR Watchdog continuously monitors each SCR. In the event of an SCR failure, the remaining SCRs are phased back and the AC power is removed. This feature protects the rest of the SCRs from failure.

Reduced Ripple

Ripple is the amount of AC that appears as voltage fluctuations on the DC output. Because some metal finishing applications cannot tolerate excessive ripple levels, Dynapower offers power supplies with ripple as low as 1% of the operating set point.

Polarity Reversing

All SCR rectifiers can be built to include solid-state reversing capabilities. This is achieved using a separate set of thyristors and electronics.

Digital Ampere-Hour / Minute Meter

Totalizing, preset counter and solution metering configurations are available to meet process and EPA requirements.

Computer Interface

Allow isolated connections of a rectifier to a computer or PLC. The computer or PLC can send voltage and/or current control signals to the rectifier, and in return receive signals from the rectifier proportional to the output voltage and/or current. Available in Analog, Modbus, Profibus, ethernet and DeviceNet.

Variable Timer

Timers are available to turn the rectifier off, sound an alarm, illuminate a light (or any combination) at the end of a process cycle.

Variable Ramp

When AC power is applied to the rectifier, the DC output will ramp up from zero to the preset output over a specific time. Fifteen different ramp time ranges can be selected through a convenient DIP switch. The ramp time is variable from 1% to 100% of the selected range. When the predetermined output level is reached, the power supply will automatically maintain a constant output for the duration of the cycle.

Automatic Current Density

The DC output is varied in direct proportion to the load, maintaining an average current density over varying load sizes.