- Home

- Companies

- UT Pumps & Systems Private Limited - A ...

- Products

- De-Scaling Systems

De-Scaling Systems

The scale on steel surface is being produced due to oxidation of base material during re-heating of the billet / material. To prevent this layer from fusing into base material during rolling process, De-scaling system is used. The scale gets loosened when High pressure water jet strikes the surface between scale and base material with high pressure through strategically placed nozzles at different angular positions causing cooling of scale. The loosened scale is washed away with water at High Pressure.

- Improves quality of Rolled Product by preventing fusion of oxidized scale into base material

- Reduces Rejection by preventing surface defects of parent material

- Increases life of Pressure Rolls of Rolling Mill and reduces down time for repair & maintenance

- Improves productivity & efficiency by eliminating trimming pass for Billets.

There are two types of Decaling System

DIRECT DESCALING:

Direct De-scaling system, the de-scaling is being done directly from High Pressure Triplex Plunger Pumps through Valves & De-scaling Header.

Operating Pressure range : 100 Bar to 400 Bar.

INDIRECT DESCALING:

The de-scaling is being done through accumulator, which accumulates the water at high pressure by High Pressure reciprocating pumps and use the pressurized water as and when required through emergency valve, operational valve and de-scaling Header.

The operating pressure range: 100 bar to 330 bar.

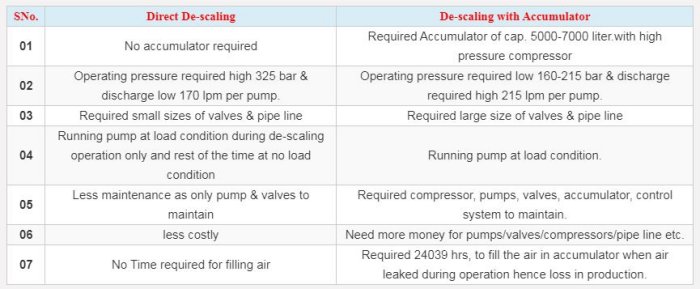

Advantages Of Direct De-scaling Over De-scaling System With Accumulator