- Home

- Companies

- BioKube A/S

- Products

- BioKube BioReactor - Decentral ...

BioKube BioReactor - Decentral Wastewater Treatment Plants

FromBioKube A/S

The BioKube BioReactor is most commonly used for treating wastewater from smaller villages and factories and retro fit with daily wastewater outlet of more than 100 m³. The system is designed for placement in in-situ casted concrete tanks.

Most popular related searches

decentralized wastewater treatment plant

bioreactor system

concrete tank

decentralized wastewater treatment

wastewater treatment plant

septic tank

decentralized wastewater

septic tank cleaning

wastewater treatment

bioreactor

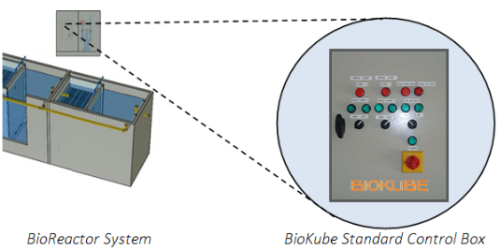

- All electrical component in the BioReactor system; e.g. blowers, pumps, UV-units , are integrated and connected to the BioKube Standard Control Box, from where the power is distributed and controlled.

- The Control Box is placed in and external weather protected shed (see drawing).

- The plant is normally powered with 340 Volt, 3 phase power supply.

- Systems for 110V power supply regions can be supplied upon request.

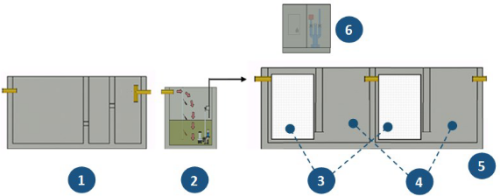

A full BioReactor installation typically consists of the following major parts and cleaning steps

- Septic Tank

- Clarifying Zone

- Buffer Tank

- Tanks for ”3” & ”4”

- BioReaktors

- Shed with Control Box and Blower

A complete system can consist of multiple BioReactor Units modular installed in parallel and 1-4 units in series. For more information see the installation manual.

Construction Principles

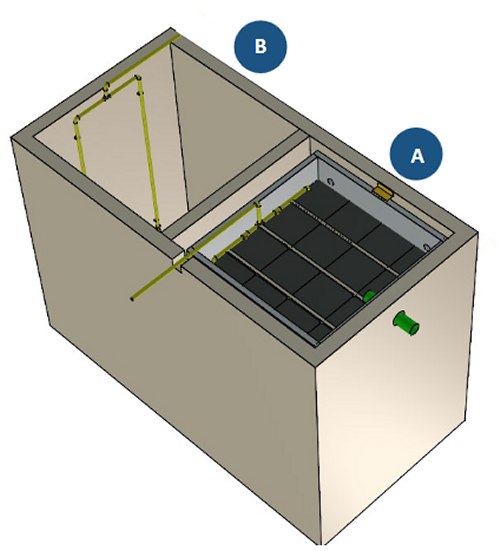

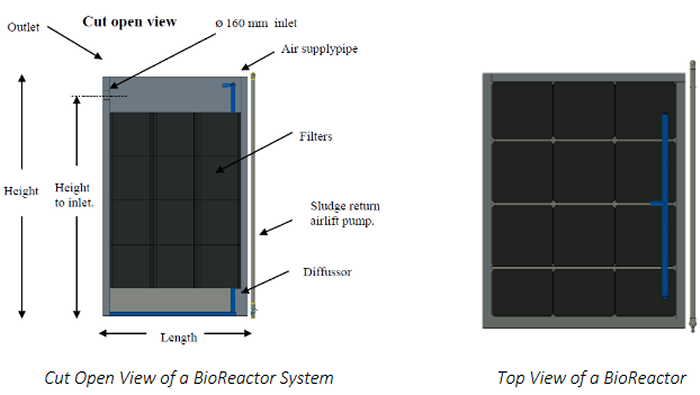

Each BioReactor units must be installed in a concrete tank forming space for (A) the treatment unit and a (B) clarifying zone.

- A The concrete tank for each of the treatment zones should be at least 10 cm wider and 50 cm deeper than the BioReactors.

- B The clarifying zone is recommended to have a size that allows for a minimum of two hours retention time and a surface area to secure maximum uplift speed of 1 m/h.