- Home

- Companies

- PURitech Gmbh

- Products

- PURItech - Model PURIclean - Diesel ...

PURItech - Model PURIclean -Diesel Particulate Filter Cleaning Equipment

PURItechsets new standards for effective and smooth cleaning of diesel particulate traps (the optimal solution for catalytically coated filter modules). The latest product from our innovation lab represents an entirely new generation of compact and modular cleaning machines.

Ultimate Cleaning Efficiency

- Patented "precision pulse" – Compressed Air System

- Smooth leaning without thermal treatment

- Short process time

- Innovative diagnosis equipment

- Already useful for EURO 6 / TIER 4 filter systems (OEM Certified)

- For all existing Wallflow filter monoliths

- CE and ATEX Certification

The Technologies of the new PURIclean System are a consequence of many years of experience with filter cleaning process; hardware and controls are unique. The ultimate cleaning efficiency allows nearly the same mileages like a new filter, even after several cleanings.

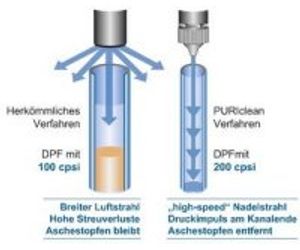

The revolutionary air nozzle forms “high-speed" needle-shaped jet stream. The high impulse impacts the harsh ash-plug at the end of every filter channel. Only if the ash plug is fully removed, a filter is as clean as a new one.

Other cleaning devices utilize a wide-spread air stream which cannot reach the bottom of the filter channel. Hence, ash plugs remain and leave the filter with lower storage capacity and regeneration efficiency.

In contrast to other cleaning methods, PURIclean removes also compacted ash debris in the monolith channels.

The PURIclean process guarantees that:

-

Every filter channel is free of ash and other debris

-

The maintenance interval and ash capacity reaches nearly the same level like a new filter

With PURIclean you avoid negative consequences of an incomplete or improper cleaning, such as:

- Substantially higher fuel consumption, reduced engine power, increased engine wear

- Reduced storage capacity resulting in more frequent filter maintenances (3 times more often)

- Replacement of the filter due to chemical or thermal aging of the catalytic coating

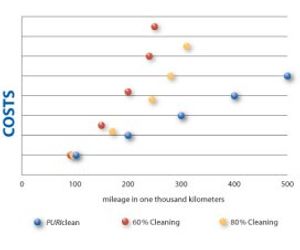

Cleaning with the PURIclean process results in significant cost savings, due to:

- Constantly long cleaning intervals

- Reduced or no downtime

- No fuel penalty

- Unchanged regeneration behavior

PURIclean efficiently and smoothly cleans not only PURItechfilters, but also other brands and filter modules. The machine is capable to run automated processes.

It is supported by the patented Diagnosis system for detection of filter disintegration and cleaning efficiency.

PURIclean is certified according to CE and ATEX standards and herewith fulfils highest expectations. Core element is the “Precision Pulse Technology”. In conjunction with the “High-Tech Heat Regenerator” and the dust collector, it guarantees highly efficient filter cleaning. Optional PDC-Modules for quality inspection, installation, maintenance and training can be ordered.

For fast and reliable inspection of DPF’s, PURItech developed a range of innovative and patented test devices.

These diagnosis systems are part of the PURIclean process and enable us to offer a “ring exchange” for filters. This method substantially reduces downtime in the workshop.

- PURIvision(optical detection of substrate disintegration; cracks, hotspots)

- PURItest(unique testing of cleaning efficiency by segmented back-pressure)

- PURIdeep(deep sounding of channel length)

Main Dimensions:

- Required Space : 800mm x 1200mm (WxD)

- Working Space : min. 1600mm x 1200mm x 1900mm (WxDxH)

- Weight:200 kg

Connections:

- Compressed air: 8bar - 1000l/min, dehumidified and not oiled

- Electrical : 400V / 50Hz / 1,5 KW / 16 A (Optional 230 V); separate grounding (PE)

Exhaust:

- Filtration of the exhaust air through HEPA filtration with integrated dust extraction

- Exhaust air can be discharged in the room

Certifications:

- CE

- ATEX