- Home

- Companies

- Process Analysers Systems Ltd

- Products

- PAC Cambridge Viscosity - Model ...

PAC Cambridge Viscosity - Model VISCOpro 1600 -Digital Viscometer

The VISCOpro 1600 digital viscometer is a compact workhorse instrument for applications where minimal operator involvement is desired. This digital viscometer features built-in optional LCD display with readout in centipoise, cSt, or SSU for monitoring of critical fluid conditions. It also can be connected to a PLC controller for seamless integration into a proprietary data management system. The unit’s sensor and electronics are encased in an explosion-proof housing for durability and reliability. Wide choice of sensors. ATEX and FM options.

In process environments, ensuring proper viscosity is a key success factor. You need an accurate, reliable, and durable in-line viscometer capable of monitoring fluid resistance without requiring a lot of operator involvement or maintenance.

You need the Cambridge Viscosity VISC0pro160O viscometer. Used alone or in a multi-channel configuration controlled by a touch-screen display, the VISCOpro1600 provides round-the-clock monitoring you can rely on.

The VISCOpto 1600 viscometer is a compact workhorse instrument for applications where minimal operator involvement is desired. It features built-in optional LCD display with readout in centipoise, cSt, or SSU for monitoring of critical fluid conditions. It also can be connected to a PLC controller for seamless integration into a proprietary data management system. The unit`s sensor and electronics are encased in an explosion-proof housing for durability and reliability.

Thanks to Cambridge Viscosity`s patented technology, only a very small amount of fluid (1 ml) is required to assure an accurate reading. Because of the small sample size and its automatic operation, the VTSCOpro 1600 helps to maximize the efficiency of your process line and minimize waste. In addition, it works with any Cambridge Viscosity in-tank or in-line 300 series or 500 series sensor, giving you the flexibility to choose from a range of high-quality, maintenance-free options.

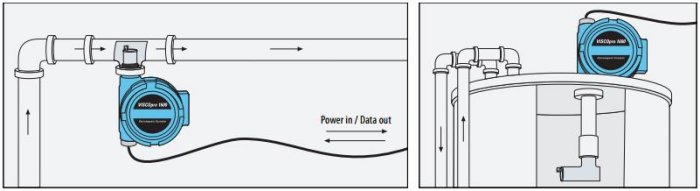

Diagram 1 (above) depicts an in-line installation of a VISCOpro 1600 with anSPCSU sensor. Its flexible design allows it to be installed in any position. Demonstrating the viscometers flexibility, diagram 2 (above right) depicts an in-tank installation of a VISCOpro 1600 with an SPU21 sensor.

Optional Display

The optional explosion-proof display (right) clearly shows viscosity and temperature readings for each line or tank.

Key Features and Benefits

Innovatively designed, the VISCOpro 1600 has a lot to offer. Among its key features and benefits are:

Automatic Self-cleaning

With only one moving part, a piston, the VISCOpro 1600 is almost completely maintenance-free. Samples are automatically kept fresh and clean by the constant piston motion that scrubs the sensor chamber. This assures maximum uptime and high return on investment.

Standard Outputs for Data Capture

The VISCOpro 1600 includes two 4-20mA outputs for remote recording to data acquisition and control systems. This makes it easy to interface the unit with Cambridge Viscosity or third-party PLC systems.

Factory Settings

No programming is needed – Cambridge Viscosity did it all for you so you can just install it and begin operation quickly. The VISCOpro 1600 can be set to measure viscosity in centipoises, cSt, or SSU.

Built-in Temperature Detector

Changes in temperature within the process line can affect the viscosity of the fluid. The VISCOpro 1600 has a built-in temperature detector that senses the actual running temperature of the fluid.

- Continuous monitoring of viscosity, and temperature

- Two 4-20mA outputs for remote recording

- Two analog outputs and RS485 communication

- Compact, explosion-proof system

- Automatic self-cleaning

- Readout in centipoises, cSt, or SSU

- Optional LCD display

- Power input: 12VOC12W

- Outputs: {2) 4-20mA; 1 RS485

- Accuracy: +/-1.0% of full scale (correlates to ASTM 0445)

- Repeatability: 0.8%

- Ranges: 0.2-20(0OOcP {0.2-2cP( 0.25-5cP( 0.5-10cP( 1-20cP( 2.5-50cP( 5-100cP, 10-200cP, 25-500cP, 50-1,000cP,100-2,000cP, 25O-5,0OOcP,5O0-10,O0OcP, 1,000-20,O00d>)

- Wetted Components: Standard 31617430 Stainless Steel, Optional Hastalloy and Sanitary Components

- Temperature Range: -40°Cto190°C(375°F)

- Maximum Operating Pressure: 1000 psi (70.3 bar)

- Temperature Sensor Type: 4 wire Platinum RTD

- Certifications: FM, 3A, CE, ATEX - EExdIIC, |EEx d IICT4, -20C<Ta<95C (For SPL Models), EEx d IICT2, -20C<Ta<190C (For SPL Models)] Factory Mutual - Class 1 Div.l, Group C, D:T3 NEMA4, IP-66 (Sensor model 571 - only CE certified. Ranges differ, call factory)