- Home

- Companies

- MKR Metzger GmbH

- Products

- MKR - Model OSD 1000 - Disk Centrifuges

MKR - Model OSD 1000 -Disk Centrifuges

Specific Characteristics: Throughput 800 – 1500 l/h, Pre Filter 350 µm, Automatic Disludging, Handling via Siemens S7, Fully Automatic Process, Adjustable Flow Rate.

- User friendly operation

- Cleaning without stopping the machine

- Precise removal of tramp oil

- Fine cleaning ›2 µm

- No consumable filter materials required

- Electrovalve for the feed and feedback pipeline

- Pre filter (stripping filter)

- Foreign oil pump set

- Switch cabinet-wiring-mark

- Suction System with magnet base 60/100 strokes

- Suction System with magnet base 110/180 strakes

- Suction System Free Floating

- Custom Colour

Housing

Weldment of 3mm steel sheet, at the same time designed as a collecting basin.

Varnish

Double coating inside and outside 2-K-varnish (NCS-S 2010-R70B)

Hoses Ø 25 mm

Suction hose length 4 m,

Recirculating hose cleaned medium length 4 m,

Sludge- and oil-recirculating hose, length 3 m

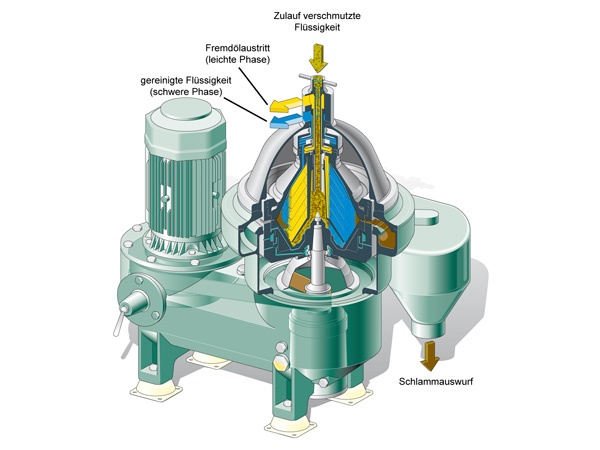

Separator-system

Self-discharge disk separator 3-phase-separation, power 800 - 1500 l/h

Separator parts, which are in contact with the medium, are made of stain- less steel

Outflow system

Sludge tank

Diving pump 0,21 kW, 380/440V, 50 Hz

Pre-filter as pump protection

Single filter, stainless-steel-insert 350 μm

Switchgear cabinet

Equipment for automatic operation,

Control, SIMATIC S7 / 300, OP 7

Rotary field identification

Electricity cable 10 m, 5-pol.

Options

Control water-rise of pressure-system

With this appliance the steering water is put in cycle to open and close the drum.

Advantages:

- The water-connection at the system is only necessary for the refill of the control water tank

- Steering water consumption is strongly reduced.

Components:

Feed tank made of stainless steel, Level control, Float valve with fresh-water connection, Pressure pump with pressure compensation tank

Foreign oil pump set

This appliance is needed in order to lead back the separated foreign-oil higher than 2m. The foreign-oil-phase is buffered in a container and is pumped back with a level-controlled pump.

Components:

- Tank volume approx. 80 l

- Level control from float switches

- Pumping capacity 5 l/min. at 10 m height

Pre-filter (stripping filter)

In order to protect the disk separator against larger particle quantities, we build in an automatically cleaned pre-filter which cleans itself in the feed conduct.

System components:

- Filter-fineness 200μm, alternative 100 μm

- Metal edge filter with drive

- Pressure switch

- Sludge drain valve electro-pneumatically

Switch cabinet-wiring-mark

According to standard all strips and construction units in the switch cabinet are designated.

With this option additionally all wire´s in the switch cabinet are numbered.

Electrovalve for the feed and the feedback pipeline

To avoid overflow, this option is necessary. If the liquid level is higher than the MKR system, a back flow out of the tanks that has to be cleaned is possible at a malfunction or rather machine down time.

Medium stability up to pH 13

Medium-affected parts in stainless steel

Documentation

Operation manual, wiring diagram