- Home

- Companies

- Komline-Sanderson

- Products

- Komline-Sanderson - Dissolved Air ...

Komline-Sanderson - Dissolved Air Flotation Clarifier

Komline-Sanderson Dissolved Air Flotation Clarifier is suited for wastewater streams containing solids, oils, and greases, which are difficult to settle or have a tendency to float. With proper chemical conditioning we remove colloidal and emulsified materials. Complete pretreatment systems can be supplied.

With proper chemical conditioning we remove colloidal and emulsified materials. Complete pretreatment systems can be supplied.

- High rate design

- High removal efficiency

- Meet effluent discharge requirements

- Recovering suspended material

- Reclaiming water for reuse

- Thickening of slurries and sludges

The Komline-Sanderson Dissolved Air Flotation Clarifier is designed for the removal of suspended solids or water immiscible liquids from process or wastewater to produce an effluent of high clarity and free of objectionable particles or liquid. Dissolved air flotation is best applied to remove materials that normally settle slowly, persist by remaining in suspension, or have a tendency to float.

- Aircraft Maintenance

- Algae Removal

- Automotive Industry

- Bakery Waste

- Ballast Water

- Canning

- Chemical Processing Plants

- Fiber Recovery

- Heavy Metal Recovery

- Latex

- Meat Packing

- Paint Waste

- Pet Foods

- Pharmaceutical

- Potato Processing

- Poultry Processing

- Prepared Foods

- Pulp and Paper Mills

- Refineries

- Rendering

- Seafood Processing

- Slaughter House

- Tank and Truck Cleaning

- Tanning

- Textiles

- Vegetable Oil

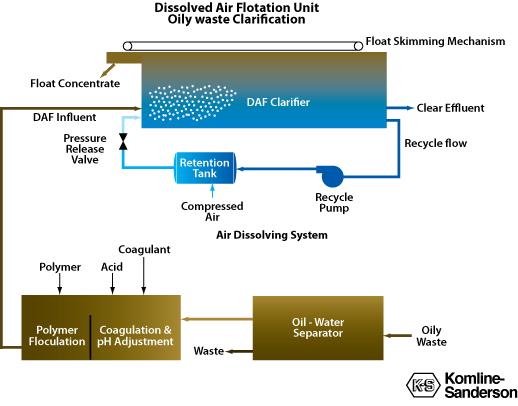

- Wastewater is pretreated with chemicals.

- Treated influent is fed to DAF unit.

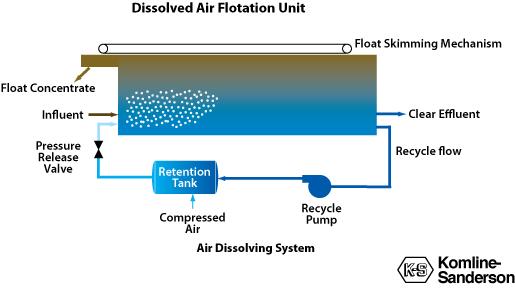

- Recycle is drawn off effluent line and is sent through the air dissolving system and then sent back into the DAF.

- Air is released from the recycle flow and the bubbles help to float solids in the DAF tank.

- Float is skimmed from the top of the tank.

- Clear effluent flows out of the unit.

How do I know if a K-S DAF is right for my process?

Does your process involve:

- Clarification of a wastewater stream

- Reduction of TSS, COD, and BOD to meet effluent discharge limits

- Recovery of suspended material

- Reclaiming water for reuse

- Thickening of slurries and sludges

Are you interested in:

- Minimal operator attention

- Low maintenance time and expense

- A well-built machine offering long equipment life

If you can relate to these objectives, then follow these steps:

- Establish influent and required effluent conditions as accurately as possible

- Complete the K-S Applications Questionnaire

- Contact us to assist in making a preliminary selection

- Perform lab and/or pilot scale testing if necessary

- Make final selection

Other considerations:

- What is immediately upstream and downstream of the DAF?

- What is most important: floated solids concentration, effluent clarity, capital or operating cost, etc.?

- What have you tried before? Why did/didn`t it work?

- What materials of construction are acceptable? What are not?

- Do you need auxiliary equipment, such as chemical pretreatment, for example?

- Do you need any instrumentation or controls?

- Do you have any standard specifications?

There are many factors affecting the operation of a clarification process. Among these are chemical pretreatment; power, water, air, or other utilities; operator attention; cleaning requirements; and maintenance needs. All of these should be considered when selecting a wastewater clarification system.

K-S DAF offers

- Continuous operation

- Application versatility

- Ease of operation, requiring minimal attention

- Simple, durable design for low maintenance and long life

How can we help you?

Komline-Sanderson has been a leader in liquid/solid separation equipment design and manufacturing for over 60 years, meeting the needs of both industrial and municipal clients. Our equipment operates worldwide in an ever-growing range of process and wastewater applications. Expert process insight, outstanding customer service and high quality equipment make K-S a valuable partner throughout the project cycle.

Lab and pilot testing service is available to assist in equipment selection and sizing.

Komline-Sanderson Dissolved Air Flotation Clarifiers are designed to meet each client’s specific process needs.

The design of the flotation tank using either a flat or v-shaped bottom depends on the characteristics of the influent. Bottom collectors are sometimes used to remove solids that might settle at the bottom of the tank. The air dissolving system on the K-S DAF Clarifier ensures the efficient mixing of air into the recycle water from the flotation tank. A top collector skimmer assembly is used to remove concentrated float from the tank. The floated material is skimmed to a discharge hopper at one end of the tank.

K-S process and project engineers provide assistance at all phases of the project. Depending on your specific requirements, K-S can provide you a DAF Clarifier only or a complete system. A successful plant depends on the integration of the key process units with properly selected ancillary equipment and the right facility design. Reliability, ease of operation, rugged construction, performance, and the superior customer service are all trademarks of a K-S installation. A typical system includes the DAF unit with recycle pump and air dissolving system as well as chemical pretreatment tanks, mixers, and pumps. Depending on customer needs, concentrated float dewatering equipment can also be provided. Controls and instrumentation are available to complete the system.