- Home

- Companies

- Buckau-Wolf GmbH

- Products

- Buckau-Wolf - Distribution and Fill-Up ...

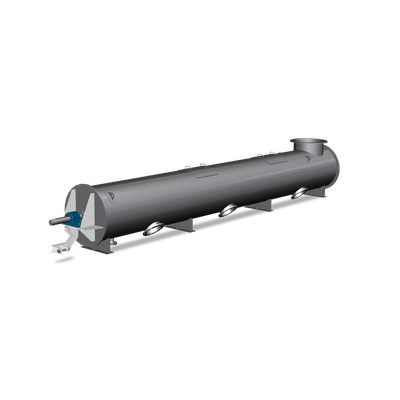

Buckau-Wolf - Distribution and Fill-Up Tanks for Crystallization

Buckau-Wolf distribution tanks are specifically engineered to meet the unique requirements of the crystallization process in sugar manufacturing. Drawing on extensive experience, these tanks are designed to handle massecuite post-crystallization, ensuring its movement and further sugar crystal growth during the cooling phase. The integral role of these tanks is to maintain constant motion and even distribution of massecuite to the centrifugals, acting as a crucial intermediate step between fill-up tanks and centrifugals. Constructed with stainless steel for all contact parts, they emphasize durability and hygiene. The incorporation of low-maintenance seals effectively prevents leakage, while a standard gear motor powers the system, enhancing reliability. Custom-designed to align with customer-specific applications, these tanks exemplify Buckau-Wolf's commitment to technical excellence in sugar technology.

Buckau-Wolf distribution tanks are designed, built, produced, and commissioned according to specific customer requirements and based on Buckau-Wolf's long years of experience.

Buckau-Wolf fill-up tanks receive the massecuite after crystallisation from the vaporising crystallisers. Stirrers keep the massecuite in motion at all times and enable additional sugar crystal growth during controlled cooldown. From here, the massecuite goes directly into the filling tank, which supplies the massecuite to the centrifugals.

Buckau-Wolf distribution tanks are the intermediate steps between fill-up tanks and centrifugals in the crystallization process. They assure that the sugar crystal suspension is constantly in motion and equally distributed to the centrifugals.

Buckau-Wolf distribution tanks are specified to match customer applications and requirements. All parts in contact with product are made of stainless steel. Specially designed, low-maintenance seals prevent undesired escape of massecuite at the face-side bearings. A standard gear motor is used as the drive.