- Home

- Companies

- Dosch Messapparate GmbH

- Products

- Dosch - Flow Nozzles

Dosch - Flow Nozzles

Nozzles are used as differential pressure devices to measure the flow of aggressive and non-aggressive gases, vapors and liquids. The pressure loss is lower compared to orifices. For this, higher measurement uncertainties must be expected in some cases. In terms of uncertainty and pressure loss, nozzles represent a middle ground between Venturi tubes and orifices.

There are basically three types of nozzles: ISA 1932 nozzles, long-radius nozzles and Venturi nozzles. Depending on the application, each design has its advantages. In the following we briefly present the three designs. All variants can be designed as single-flange nozzles or weld-in nozzles, see the relevant brochures on the right.

Standard flow nozzles consist of circular inlet profile and a cylindrical outlet part. The pressure taps are designed either as single bores in a single carrier ring or as ring chambers with two carrier ring halves.

The measuring uncertainty depends on the process conditions and amounts to approx. 0,8% – 1,2% of the flow coefficient.

Long radius nozzles consist of a quarter circle inlet profile and a cylindrical outlet part. The pressure taps are located 1D in front of the nozzle and 0,5D behind the nozzle (D = pipe inner diameter).

The measuring uncertainty depends on the process conditions and amounts to approx. 2% of the flow coefficient.

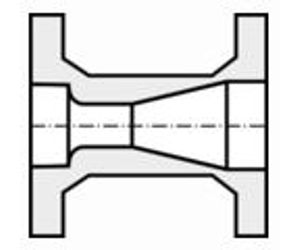

Venturi nozzles consist of circular inlet profile, a cylindrical middle part and an outlet cone. Normally, the plus side pressure tap is designed as a single bore. The minus side pressure tap is usually implemented as four bore holes which end in one ring chamber or annular ring.

The measuring uncertainty depends on the process conditions and amounts to approx. 1,2% – 1,8% of the flow coefficient.

Typical pressure tap designs are as follows:

- Plain ends for fittings

- Butt weld ends

- Threaded ends

- Flanged ends

Welding avoids sealing problems which may arise with high pressures and temperatures. All three nozzle types may be offered as weld-in types. If needed, we can include welded inlet and outlet pipe ends. The welding seam is processed after welding in order to meet the pipe roughness requirements of the respective calculation standard.

We can offer instrument valves and/or manifolds for your nozzles. For steam flow measurement we recommend our condensate pots.

Pressure tapping connection

Typical types of discharge nozzles are:

- smooth nozzles for screwed connections

- Welding spigots

- Threaded nozzles

- nozzles with flanges

- Weld-in versions

For high pressures and high temperatures, it is advisable to use a nozzle for welding in to prevent leaks. All three designs can be manufactured as weld-in variants. On request, pipe ends, usually provided, can also be welded on at the inlet and outlet. In this case, the weld seam is machined on the inside after welding in order to guarantee the requirements of the calculation standard for the pipe condition. For details see the brochures on the right.