- Home

- Companies

- Dosch Messapparate GmbH

- Products

- Dosch - Model EBLB 800 / EBLA 800 - ...

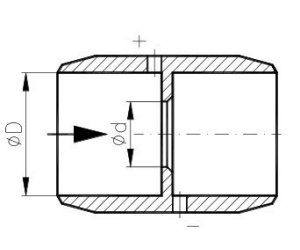

Dosch - Model EBLB 800 / EBLA 800 -Weld-in Orifice

Generally, weld-in orifice plates are utilized for high pressure and high temperature applications, e.g. in power plants. They can be manufactured with (EBLA 800) our without (EBLB 800) a ring chamber tapping. If needed, we can weld inlet and outlet pipe sections to the orifice plate. These pipe sections usually are provided by the customer. The welding seams are mechanically processed in order to meet the surface roughness requirements of the respective calculation standard.

Weld-In orifice plates are used as flow elements for flow measurement of aggressive and non-aggressive gases, steam and liquids.

Weld-In flow elements are the recommended choice for high pressure and high temperature application because they avoid any kind of leakage.

The single bore tappings (EBLB 800) are easy to clean and thus suitable for process fluids which may have some solids, may be resinous or for plants which are not operating constantly. The ring chamber design (EBLA 800) ensures that the pressure values are averaged over the cross section. This results in a steady measurement signal.

Between 0,5% -1,2% of the discharge coefficient C, depending on the application.

The pressure loss depends on the diameter ratio p (d/D) and amounts to approx. 30 - 80% of the differential pressure.

DN 50 to DN 1000 / 2" to 40" (if requested other sizes are possible)

PN 40 to PN 400 /150# to 2500# (ASME)

Weld preparation according to EN ISO 9692 (DIN 2559), ASME B16.25 or customer standard.