- Home

- Companies

- Aerodyne Environmental - A Sister ...

- Products

- Aerodyne - Model GatorGate - Double ...

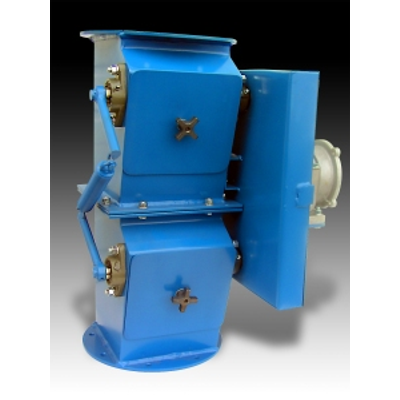

Aerodyne - Model GatorGate -Double Dump Valves for Dry Material Handling

The GatorGate Double Dumpvalve feeds and moves chunky or fibrous material that would jam ordinary rotary valves and is durable enough to move abrasive material. The GatorGate valve uses tandem gates to maintain proper pressure above and below the valve and has a reinforced closure mechanism to prevent air seepage. This double flap valve can be configured to operate using air or electricity and requires little maintenance.

- Heavy duty carbon steel fabrication

- Heavy duty gear reducer and cam mechanism

- Stainless steel fabrication available

- Low leakage air design

- 8″ – 1.42 cubic feet per minute

- 10″ – 2.7 cubic feet per minute

- 12″ – 5.3 cubic feet per minute

A double dump valve has twin chambers, each with a door that opens to dispense material. The cam operation is such that a door opens only when its chamber is sealed by an internal flap. The doors open alternately to permit a steady flow of material. While one chamber is collecting, the other is dispensing.

A double dump valve is used in a dry material handling system where a loss of positive or negative or positive pressure is not acceptable. For this reason, it is an excellent alternative to a rotary valve or knife gate valve. A double-dump valve is also better able to handle large and rough materials that could jam a rotary valve and because its design avoids wear.

Double dump valves are used with materials that are free flowing and not sticky. They are used to discharge material from hoppers, dust collectors, and baghouses. Usually ,their operation is powered by an electric motor.

Aerodyne’s GatorGate Double Dump Valve easily handles abrasive and fibrous material with minimal wear and air seepage.