Toro Equipment S.L.

- Home

- Companies

- Toro Equipment S.L.

- Products

- Draco - Model FPM Series - Manual ...

Draco - Model FPM Series -Manual Filter Press

The sludge filter pack opening and closing system is operated mechanically by means of a lever. Cake discharge by means of a scraper. Capacity: Maximum filtering surface: 1.5m² to 64.3m². Maximum number of plates: 5 to 60. Plate size: 470mm to 800mm.

Most popular related searches

filter press

automatic polyelectrolyte plant

sludge conditioning tank

manual filter press

sludge conditioning

sludge management

high capacity drainage

boring machine

tunnel boring

drainage capacity

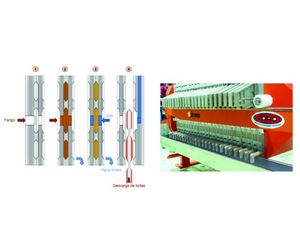

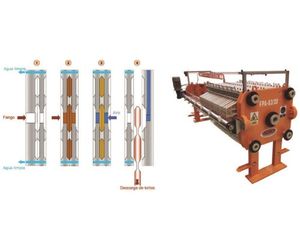

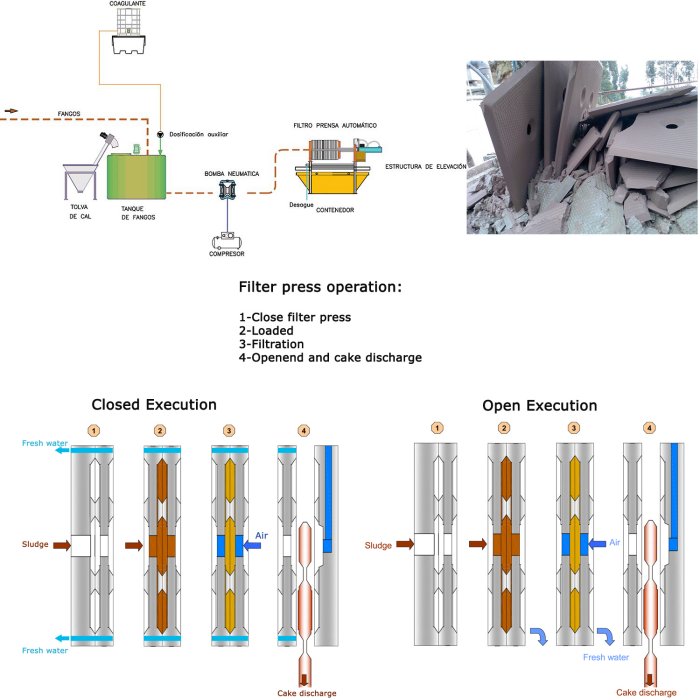

Open execution

- Override option with the installation of different taps.

- Allows easy inspection of the quality of the filtered liquid.

- Allows quick location of damaged/broken fabric.

- Suitable for preventing the drained water from coming into contact with the outside to protect it from contamination.

- Ideal for working with hazardous products.

- It also allows the cleaning of fabrics and the blowing of cakes.

- The range of filter press consists of five different models

- Extend the life of your equipment with materials manufactured using environmentally friendly processes.

- All machines, regardless of model and size, are characterised by:

- Manufactured in stainless steel St 37-2, AISI 304 and GRP.

- Epoxy paint surface finish to protect them from possible corrosion.

- Draco® Filter Presses achieve greater dryness, reducing the cost of managing the sludge generated.

- Easily transportable sludge. Problems such as liquid overflow in the containers are avoided.

- Sludge can be stacked once dewatered. The high degree of dryness facilitates sludge management, composting and logistics.

- Total reliability 24 hours a day. Unattended operation thanks to the cake shaking system.

- Low process water consumption.

- Minimal maintenance costs.

- No need for greasing.

- 100% automated cycle operation.

- Precise control of actual sludge production.

- Fairings that favour more hygienic atmospheres than rotating systems.

- The sludge only comes into contact with the air at the moment of opening.

- Possibility to filter sludge directly from the biological reactor without thickeners.

- Filtration below 10 μ.

- Guaranteed flow rate in cycles longer than 24 hours.

- Low investment and high reliability.

- High drainage capacity filter press.

- Fast cycles.

- Robust operation.

- Closed execution. The material does not come into contact with the chassis.

- Chassis in stainless steel or GRP infused in isophthalic resin or vinylester with high structural and corrosion resistance.

- Special filter plates.

Fabrics

In order to obtain the maximum performance of the equipment, each filter press incorporates the most suitable filter cloth for each specific application:

- Standard fabrics.

- Fabrics with anti-drip frame.

- Fabrics for watertight plates.

- Special fabrics for the treatment of aggregates.

- Fabrics for other specific treatments.

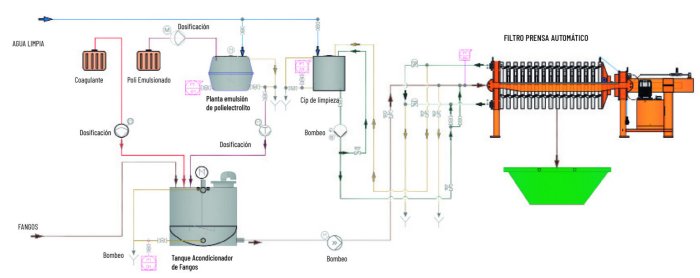

- Automatic polyelectrolyte plant

- Sludge conditioning tank

- Flocculator

- Soda dosing machine

- Polyelectrolyte dispenser

- Firefighter sludge to filter press

- Wastewater

- Wastewater for reuse

- Stone

- Aggregates

- Tunnel boring machines

- Antibiotics

- Food

- Drinks

- Chemicals

NOTE:

- (1) The FPM is supplied with side shields.

- (2) The FPM is supplied with filtrate collection channel and handles.

- (3) The dimensions and specifications may vary slightly due to the normal development of products by the engineering department or Toro Equipment SL.

- When ordering request the specifications sheet at www.toroequipment.com

On request:

- Transportation of equipment in treated wooden crates.

- Palletising and plastification of equipment.

- Containerisation.