Dustmaster - Horizontal Shaft Mixer

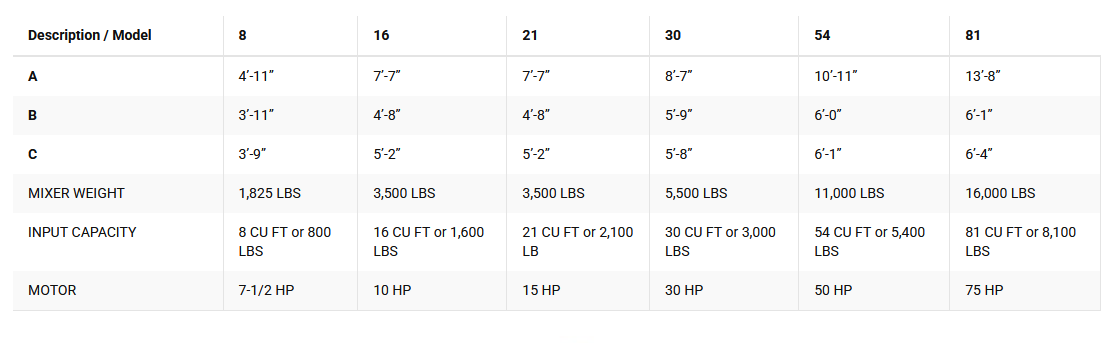

Now you can have the benefits of big system performance on low- to high-volume material handling and stabilization projects. From a compact 8 cu. ft. capacity to a large 81 cu. ft. capacity mixer, we have five sizes for your application. Each includes all of the features you would expect from DustMASTER in an economical processor. With a PLC based control system and heavy duty abrasion and corrosion resistant components, our horizontal shaft paddle mixers offer a fast mixing cycle.

Other features are: longitudinal water dispersion tubing for an even liquid stream, proven cross-current mixing action, convenient access for loading and maintenance, and built-in crane hook and forklift brackets for ease of transport. The mixer interior contains cast Ni-Hard paddles and scapers with bolted-in segmented drum liners for rapid replacement. To handle refractory mixing requirements, we offer this rugged mixer with the special capabilities to process low-moisture refractory castable materials.

- 1/4” thick drum wall on Models 8, 21 and 30

- 5/16” thick drum wall on Models 54 and 81

- 1/2” thick end plates on Models 8, 21, 30 and 54

- 3/4” thick end plates on Model 81

- 3” dia. drain in center of tank bottom

- Cast Ni-Hard drum liners

- Abrasion resistant steel side liners

- All are replaceable, bolted segments

- Cast Ni-Hard mixing paddles (or optional spiral blades)

- Abrasion resistant steel side scrapers

- Replaceable wear guards for shaft

- Sealed, self-aligning pillow block bearings

- Lubrication cup with visual level indicator and spring-operated feeder for proper lubrication

- Located in rear of drum with a rubber door seal

- Air cylinder operated linkage with hand operated valve

- Flow control valve for speed adjustment

- Air line lubricator and moisture trap

- Drivetrain

- Shaft mounted reducer on Models 8, 21 and 30

- Planetary transmission on Models 54 and 81

- Belt-driven input

- Output shaft coupled directly to mixer shaft

- Primary double-labyrinth seal and secondary “cat” seal

- Split construction for field servicing

- Both seals are purged with Vellox 3 grease

- 4-point remote lubrication panel

- Steel top cover lid

- Dual hinged access doors in front and back of mixer

- Doors include ‘doors closed’ interlock switches

- Doors and top cover are gasketed for dust containment

- One color, high grade machinery enamel

- Baghouse dust residue

- Bottom ash

- Calcium oxide

- Cupola dust

- CKD and alkaline bypass dust

- Heavy metals and iron oxides

- Fly ash

- Foundry sand

- Frac sand dust

- Hazardous and non-hazardous wastes

- Medical incinerator waste

- Municipal incinerator waste

- Low-grade nuclear waste

- Pyrites

- Shot blast

- Economizer ash

- Waste to energy