Dustmaster Enviro Systems, a division of Mixer Systems, Inc. products

Dustmaster - Pan-Style Mixer

The Turbin pan-style mixer manufactured by DustMASTER has been an industry standard for more than 70 years, legendary for the speed and quality of its mixing. With a capability of 20 to 250 tons/hour, it is suitable for processing a range of abrasive and difficult-to-mix materials. Unique concave mixing paddles and three-dimensional mixing action are keys to the Turbin’s performance. With paddles covering 600 feet per minute tip speed, the mixing action generates excellent dispersion and turns materials into a homogeneous, 100% stabilized mix. Dependent upon the type of material, the Turbin can produce a non-dusting mix in only 30 seconds with as little as 8% water (or another reagent). Two Turbin models in each of the sizes are available: DustMASTER Series I with a weigh batcher; and DustMASTER Series II with load cells under the mixer.

Dustmaster - Horizontal Shaft Mixer

Now you can have the benefits of big system performance on low- to high-volume material handling and stabilization projects. From a compact 8 cu. ft. capacity to a large 81 cu. ft. capacity mixer, we have five sizes for your application. Each includes all of the features you would expect from DustMASTER in an economical processor. With a PLC based control system and heavy duty abrasion and corrosion resistant components, our horizontal shaft paddle mixers offer a fast mixing cycle.

Dustmaster - Planetary Style Mixer

High-performing mixer for a broad range of materials. The DustMASTER planetary style mixer is a fast, efficient machine ideally suited to a wide variety of materials including fly ash, baghouse dust, foundry sands, powdered metals, cement kiln dust and dry chemicals. Counter-current mixing action achieves a homogeneous mix in as little as 30 seconds, as material is quickly mixed from top to bottom and moves opposite the direction of the paddles for thorough blending. Long-wearing and high-performing components reduce maintenance and prolong life. Capacities from .5 to 4 cubic-yards are available.

Dustmaster - Twin Shaft Style Mixing System

Providing high volume, high shear mixing, the DustMASTER twin shaft style mixing system achieves mix times of 60 to 90 seconds, with output capacities ranging from 4 to 6 cubic yards. Our Twin Shaft Mixer is designed with off-the-shelf components for ease of service and maintenance, featuring air purge shaft seals, a single drive motor, heavy duty cast steel mixing arms, abrasion resistant cast Ni-Hard lining and a hydraulic discharge door. Integrated safety features include a safety light, and warning horn. The mixing tank has a dry filling input capability of 16,000 to 24,000 lbs., or 164 to 245 ft³.

Dustmaster - Refractory Batch Mixers

At DustMASTER, we offer a full line of refractory mixers that are designed to hold up to the most extreme industrial environments. Available refractory mixers include our Prashak horizontal shaft paddle mixers, our flagship Turbin Mixer XL series as well as planetary mixers with motors ranging from 7.5 hp up to 100 hp. All are up to the challenge of mixing dry, semi-dry and low-moisture refractory castable materials. These batch style mixers are available with capacities from 3 to 81 cubic feet, with a maximum batch weight of 12,000 lbs. All components from the paddles and mixing shafts to the V-belt drive system are constructed of rugged materials and designed for maximum durability. The interior is lined with abrasion resistant steel and cast Ni-Hard to increase equipment life.

Dustmaster - Skip Hoist

Compact, space-saving skip hoists provide fast, dependable lifting for all material handling operations. Charge mixers, lift barrels, containers, scrap metal, grain—the applications are endless. Low-profile, roll-over or bottom-dump designs fits into tight work areas. Heavy-duty construction assures long life and stability on the oversized frame and track. We can modify and design the skip hoist to accept all types and sizes of containers or loose materials. Capacities are available from 3 to 100 cu. ft. Higher capacities are also available with custom design.

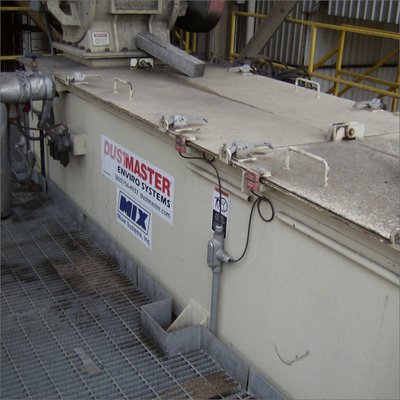

Dustmaster - Pug Mill

Built on more than 30 years of providing solutions for customers in a range of industries, the powerful DustMASTER pug mill continuous mixing systems offer cost-effective mixing for wet or dry materials. The dual shafts in this system operate independently, with a separate motor, V-belt, and gear reducer composition for sequential starting. The bolt-on paddle tips are composed of abrasion resistant cast Ni-Hard, able to thoroughly process granular and heavy materials such as aggregate. We offer a variety of pug mill models including the 50P, 125P, 250P, and 400P with available capacities ranging from 50 to 400 tons per hour, and dual motor ranges of 10 to 30 hp.