- Home

- Companies

- Dustmaster Enviro Systems, a division ...

- Products

- Dustmaster - Model Turbin - Pan-Style ...

Dustmaster - Model Turbin -Pan-Style Mixer

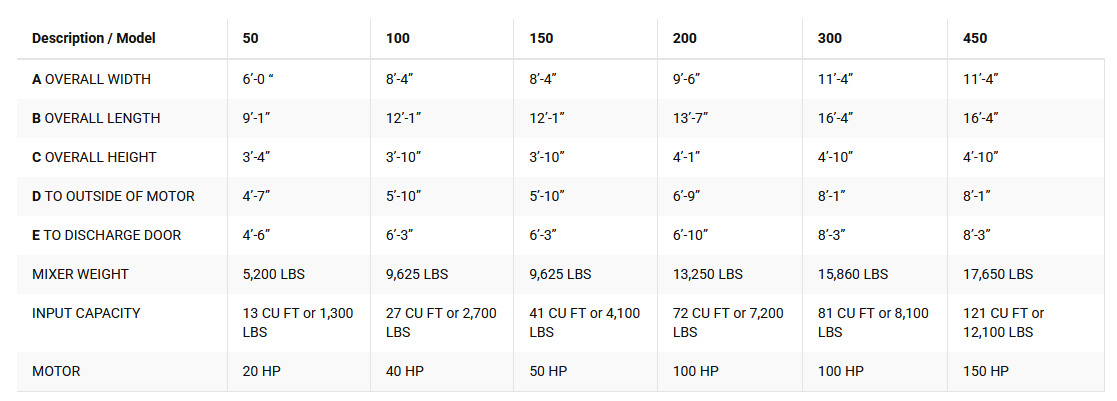

The Turbin pan-style mixer manufactured by DustMASTER has been an industry standard for more than 70 years, legendary for the speed and quality of its mixing. With a capability of 20 to 250 tons/hour, it is suitable for processing a range of abrasive and difficult-to-mix materials. Unique concave mixing paddles and three-dimensional mixing action are keys to the Turbin’s performance. With paddles covering 600 feet per minute tip speed, the mixing action generates excellent dispersion and turns materials into a homogeneous, 100% stabilized mix. Dependent upon the type of material, the Turbin can produce a non-dusting mix in only 30 seconds with as little as 8% water (or another reagent). Two Turbin models in each of the sizes are available: DustMASTER Series I with a weigh batcher; and DustMASTER Series II with load cells under the mixer.

- 3/16” thick steel tank wall

- 3/8” thick steel tank floor

- Tank is welded to structural steel channel frame

- Channel frame has lifting lugs for unloading and handling of mixer

- Abrasion resistant steel floor liners

- Abrasion resistant steel wall liners

- All are replaceable, bolted segments

- Formed steel arms with replaceable rubber wear guards

- Inside and outside replaceable cast Ni-Hard scrapers

- Cast Ni-Hard, or rubber, replaceable floor paddles

- Steel door pivots on self-lubricated sleeve bearing

- Up to three (3) doors at 90-degree increments

- Air cylinder operated linkage with discharge valve

- Flow control valve for speed adjustment

- Air line lubricator and moisture trap

- Planetary transmission

- Removable through top or bottom of mixer

- Oil lube system with pump, flow switch and reservoir

- Belt-driven from reducer to motor

- TEFC 230/460 volt, 3 phase, 60 hertz motor

- Electrically operated, automatic lubrication system

- All seals remain lubricated at all times

- Steel top cover lid

- Hinged access doors on top of mixer

- One door can have an optional hinged inspection door

- Doors are gasketed for dust and water containment

- Doors include “doors closed” safety interlock switches

- One color, high grade machinery enamel

- Baghouse dust residue

- Bottom ash

- Calcium oxide

- Cupola dust

- CKD and alkaline bypass dust

- Heavy metals and iron oxides

- Fly ash

- Foundry sand

- Frac sand dust

- Hazardous and non-hazardous wastes

- Medical incinerator waste

- Municipal incinerator waste

- Low-grade nuclear waste

- Pyrites

- Shot blast

- Economizer ash

- Waste to energy