- Home

- Companies

- Dustmaster Enviro Systems, a division ...

- Products

- Dustmaster - Refractory Batch Mixers

Dustmaster - Refractory Batch Mixers

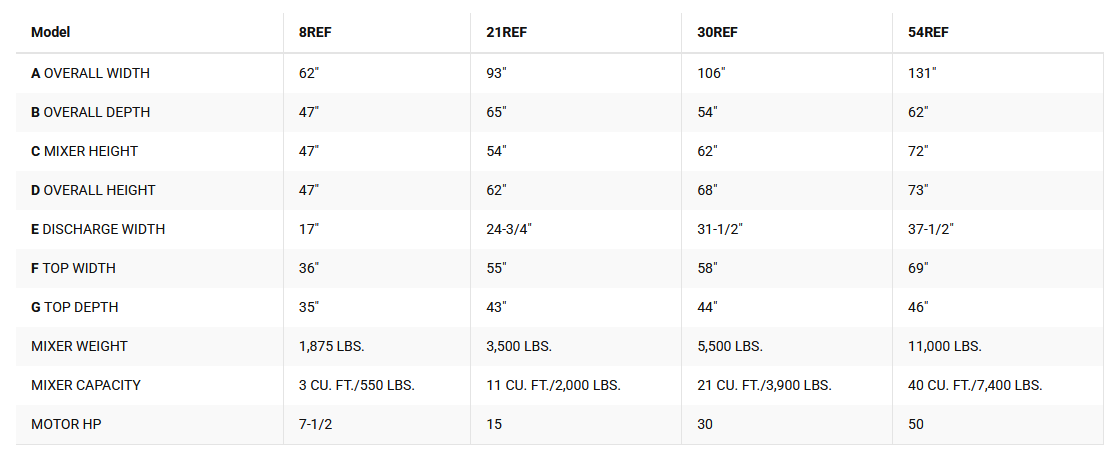

At DustMASTER, we offer a full line of refractory mixers that are designed to hold up to the most extreme industrial environments. Available refractory mixers include our Prashak horizontal shaft paddle mixers, our flagship Turbin Mixer XL series as well as planetary mixers with motors ranging from 7.5 hp up to 100 hp. All are up to the challenge of mixing dry, semi-dry and low-moisture refractory castable materials. These batch style mixers are available with capacities from 3 to 81 cubic feet, with a maximum batch weight of 12,000 lbs. All components from the paddles and mixing shafts to the V-belt drive system are constructed of rugged materials and designed for maximum durability. The interior is lined with abrasion resistant steel and cast Ni-Hard to increase equipment life.

- 1/4” thick drum wall on Models 8, 16, 21 and 30

- 5/16” thick drum wall on Models 54 and 81

- 1/2” thick end plates on Models 8, 16, 21, 30 and 54

- 3/4” thick end plates on Model 81

- 3” dia. drain in center of tank bottom

- Cast Ni-Hard drum liners

- Abrasion resistant steel side liners

- All are replaceable, bolted segments

- Cast Ni-Hard mixing paddles (or optional spiral blade)

- Abrasion resistant steel side scrapers

- Replaceable wear guards for shaft

- Sealed, self-aligning pillow block bearings

- Lubrication cup with visual level indicator and spring-operated feeder for proper lubrication

- Primary double-labyrinth seal and secondary cat seal

- Split construction for field servicing

- Both seals are purged with Vellox 3 grease

- 4-point remote lubrication panel

- Shaft mounted reducer on Models 8, 21 and 30

- Planetary transmission on Models 54 and 81

- Belt-driven input

- Output shaft coupled directly to mixer shaft

- Located in rear of drum with a rubber door seal

- Air cylinder operated linkage with discharge valve

- Flow control valve for speed adjustment

- Air line lubricator and moisture trap

- Steel top cover lid

- Dual hinged access doors in front and back of mixer

- Doors include ‘doors closed’ interlock switches

- Doors and top cover are gasketed for dust containment

- One color, high grade machinery enamel

- Fireclay

- Alumina

- Silica

- Magnesia-calcium

- Magnesia-silicate

- Low moisture castables