Dustmaster Enviro Systems, a division of Mixer Systems, Inc.

- Home

- Companies

- Dustmaster Enviro Systems, a division ...

- Products

- Dustmaster - Twin Shaft Style Mixing ...

Dustmaster - Twin Shaft Style Mixing System

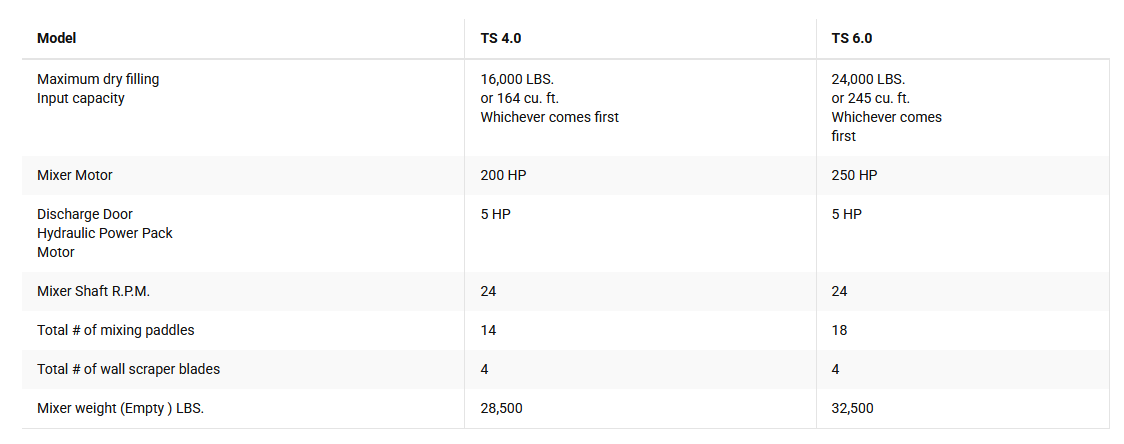

Providing high volume, high shear mixing, the DustMASTER twin shaft style mixing system achieves mix times of 60 to 90 seconds, with output capacities ranging from 4 to 6 cubic yards. Our Twin Shaft Mixer is designed with off-the-shelf components for ease of service and maintenance, featuring air purge shaft seals, a single drive motor, heavy duty cast steel mixing arms, abrasion resistant cast Ni-Hard lining and a hydraulic discharge door. Integrated safety features include a safety light, and warning horn. The mixing tank has a dry filling input capability of 16,000 to 24,000 lbs., or 164 to 245 ft³.

Most popular related searches

mixing system

non-hazardous medical waste

shut-off valve

medical waste incineration

pressure relief valve

non-hazardous waste

worm gear reducer

water distribution

hazardous medical waste

drum liner

Mixer Tank

- Mixing tank is 5/16″ thick steel, all welded construction, vertical end walls are 3/4″ thick

Liners

- Drum liners are 3/4″ thick, 550 Brinell hardness, cast Ni-Hard

- Wall liners are 3/8″ thick, 225 Brinell hardness

Mixing Elements

- Cast iron arms, mixing blades and wall scrapers are cast Ni-Hard, 550 Brinell hardness

Cover

- Four (4) access doors are hinged at the top and sealed with rubber gaskets

- All access doors are equipped with cover down safety switches which stop the power to the mixer drive if opened while mixer is running

- There are two (2) water distribution manifolds inside the cover for even water distribution

Drive

- A single electric motor, connected to a set of sheaves, drive the solid steel shaft that connects the right-angle gear reducers to two (2) planetary drives delivering even power to each of the mixer shafts

Electric Motor

- One (1) totally enclosed, fan cooled type (TEFC) motor. 460 volt, 3 phase, 60 hertz. Connected to gearbox with V-belt drive

Twin Shafts

- Two (2) 6″ square, counter rotating steel mixing shafts

- Each shaft is supported by two (2) outboard pillow block bearings and shafts are equipped with air purge seals to prevent mixing chamber leakage

Discharge Door

- Inverted, roll gate pivots from the bottom and is supported by four (4), end mounted pillow block bearings, two (2) on each end, and is powered by two (2) hydraulic cylinders

- Door runs the entire length of the mixer and has a double, rubber seal, and limit switches

- Hydraulic power pack includes a 230/460 volt, 3-phase, 60 hertz motor, 5 GPM pump, double solenoid valve, pressure relief valve, 5 gallon reservoir, 10-micron filter, sight glass with thermometer, emergency hand pump with manual shut off valve for manual opening of the discharge door

Paint

- One color, high grade machinery enamel

Warranty

- Five (5) year, limited warranty on the gear reducer.

- Baghouse dust residue

- Bottom ash

- Calcium oxide

- Cupola dust

- CKD and alkaline bypass dust

- Heavy metals and iron oxides

- Fly ash

- Foundry sand

- Hazardous and non-hazardous wastes

- Medical incinerator waste

- Municipal incinerator waste

- Low-grade nuclear waste

- Pyrites

- Shot blast

- Economizer ash

- Waste to energy

- Soil remediation