-

Electrostatic / triboelectric

-

Non-contact, non-intrusive

-

Compact design

-

Detection of only moving material - not influenced by deposits

-

Detection area: flange interior

-

Relay and 4...20mA version

-

Flow displayed by LED-bar (relay version)

-

Easy mounting between DIN- / ANSI - flanges up to 40 bar (570 lbs)

-

Reliable, longterm stable, maintenance free

- Home

- Companies

- DYNA Instruments GmbH (MÜTEC ...

- Products

- DYNA - Model DYNAguard K - Flow ...

DYNA - Model DYNAguard K -Flow Indicator for Solids

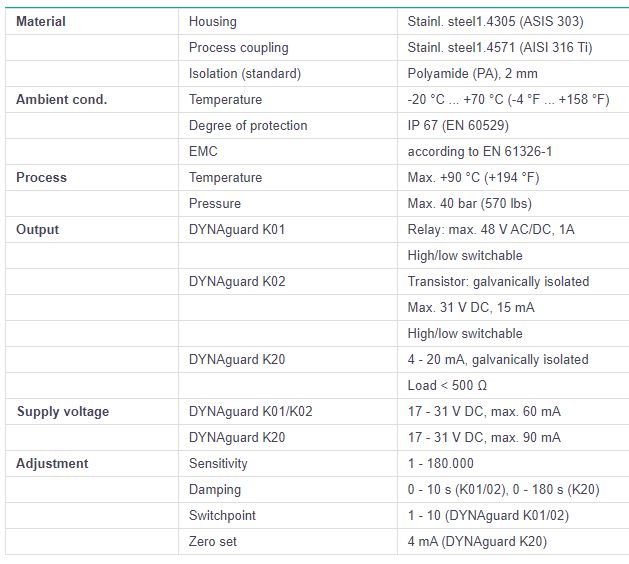

The DYNAguard K is a flow indicator for solids, designed to monitor mass flow in solid material handling applications such as pneumatic transport lines, feeders, or gravity chutes. It operates on electrostatic or triboelectric principles and features a non-contact, non-intrusive design. Only moving material is detected, making it immune to issues caused by deposits. The device's detection area is within the flange's interior and it offers versions supporting both relay and 4...20mA output. An LED-bar displays flow in the relay version. The compact unit can be easily mounted between DIN / ANSI flanges and withstand pressures up to 40 bar (570 lbs). Its reliable and stable operation helps prevent plant issues like clogging, material loss, and downtime by detecting moving electrical charges produced through friction. However, it is unsuitable for solids that create an electrical conducting layer on the sensor. This indicator plays a crucial role in ensuring smooth operation in various industrial processes.The indicator of DYNAguard K helps to monitor the mass flow in solid material handling applications such as pneumatic transport lines, feeders or gravity chutes in a wide range of mass flow from g/h to t/h.

Conveying or feeding problems of powders, pellets or granules are detected early and thus should be avoided. This helps to prevent plant failures like clogging, material loss, idle or other serious difficulties.

The meter detects moving electrical charges that are produced, for example, through friction with other objects such as the pipe wall and then naturally adhere to the solids surface solids, solid lining will not be detected.

The device is not applicable for solids which build up an electrical conducting layer on the sensor through friction or deposition.