Using state-of-the-art microwave technology the flowmeter DYNA M-flow is designed for flow measurement in metallic pipelines from a few kg/h to many t/h. The system is suitable for on-line measurement of powders, dust, pellets, and granulates.

The measurement principle of the DYNA M-flow is based on the physical Doppler-Effect, whereas the sensor generates a uniform field in the microwave frequency range inside the pipeline. These microwaves are being reflected by particles passing through the pipe. Calculation of frequency and amplitude changes allows an accurate determination of the solid's mass flow rate. Nonmoving particles like dust accumulation are excluded from calculations.

The DYNA M-flow consists of a probe, a DIN-rail transmitter, a welding branch and the PC-software DYNAvisual.

The process interface occurs by a welding branch, through which the sensor is screwed flush with the inside of the pipe. With this a flanging at perpendicular and horizontal pipes for free fall and pneumatic conveying occurs.

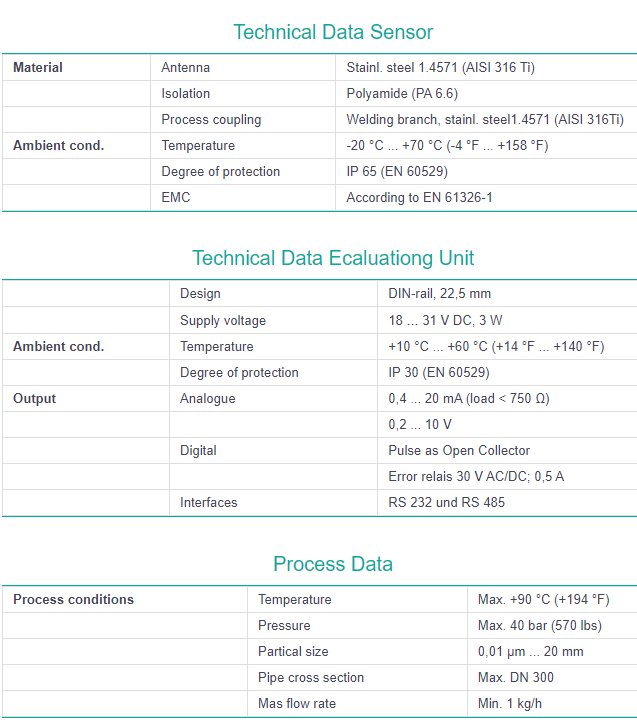

The probe is connected by a four core cable to a DIN-rail mounted transmitter with 4...20 mA, pulse output, error relay, RS232 and RS485 output.

For commissioning and calibration a notebook with our DYNAvisual software is needed. Calibration can be performed with either one or more reference points.

The measurement value is output either analogue or as digital signal. A serial COM interface is available at the front of the transmitter to connect a notebook computer and a RS485 interface for connection to a PLC system.