- Home

- Companies

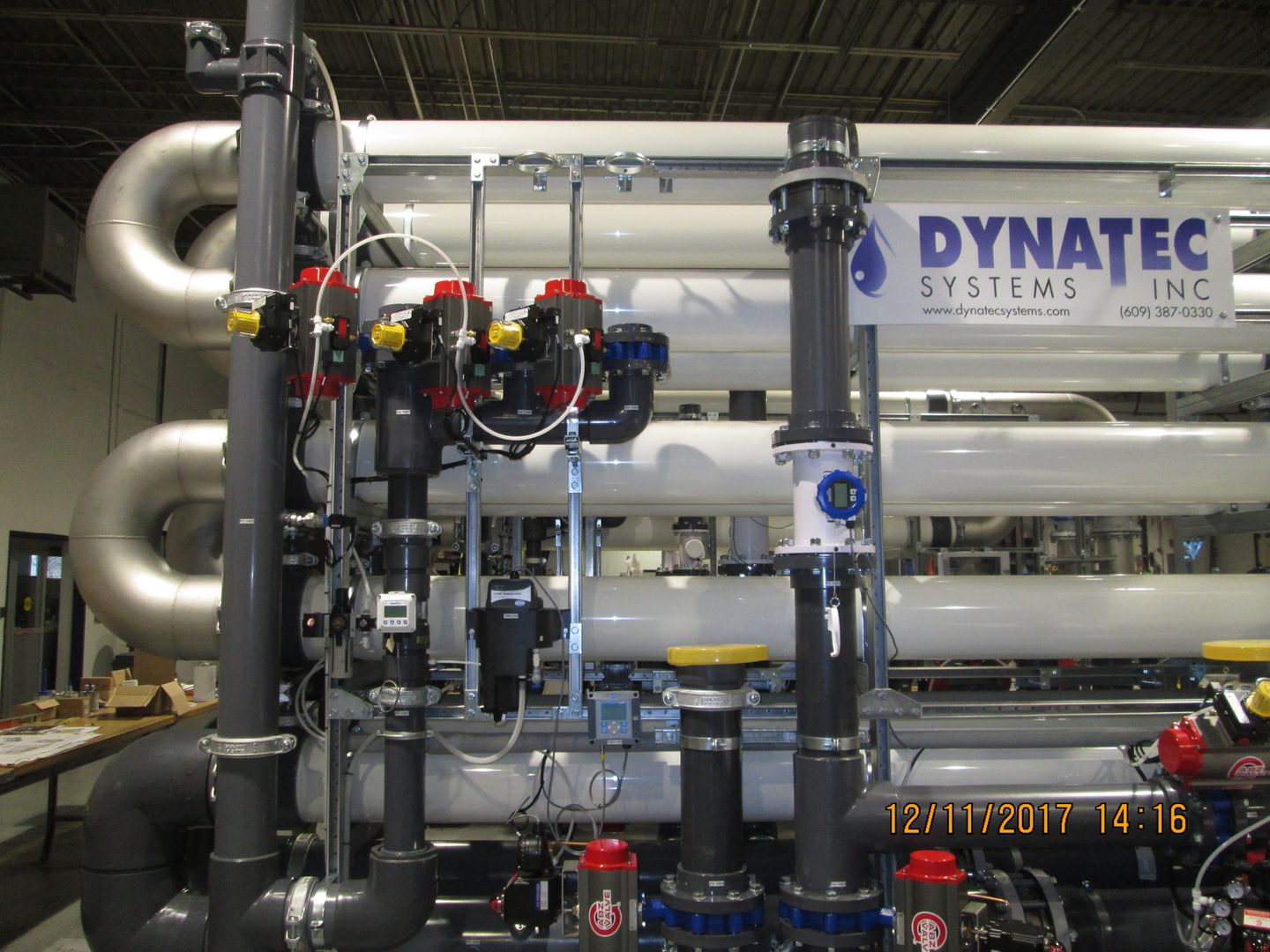

- Dynatec Systems Inc.

- Products

- Dynatec - Tubular Membranes

Dynatec - Tubular Membranes

Out-of-Basin MBR is a configuration where mixed liquor is pumped at high velocity through the tubular membrane module. The high velocity continuously scours the membrane surface and prevents solids from building up. This process produces high flux rates and simple operation. No backwash is required. Lowest capital cost option because of the high flux rates and simple operation. Out-of-Basin MBRs by Dynatec are designed so that the energy requirements are equal to other types of MBR systems.

Membrane Technologies

Membrane Technologies have several membrane configurations available for Membrane Bioreactor (MBR) applications. Project requirements should drive the decision for membrane selection.

Technologies available for use in MBRs:

- Tubular

- Hollow Fiber

- Flat Sheet

The original and most proven type of ultrafiltration is tubular membranes:

- Sturdy construction

- Long membrane life

- High flux rates

Of all membrane types, they are more robust and can be subjected to high pressures in demanding applications.

- Higher performance due to higher MLSS and long sludge age

- Low Cost

- Simple Operation

- Entire system may be placed indoors

- Membrane tank not required

There are several membrane configurations available for MBR applications.

- Tubular membranes offer cost effective, reliable systems for small plants due to easy installation and small footprint.

- Flat plate and hollow fiber membranes must be placed into a tank and serviced with cranes. Therefore, the installed costs of these systems are much higher than tubular systems for small plants.

- Tubular system installations are typically completely installed in a building without concrete tanks.

- Requirements of the project should drive the decision for membrane supplier.

For more information and to learn which membrane technology is right for your application, please contact us today.