- Home

- Companies

- Willy A. Bachofen AG

- Products

- Dyno - Model Mill Ubm - Universal ...

Dyno - Model Mill Ubm -Universal Agitator Bead Mill

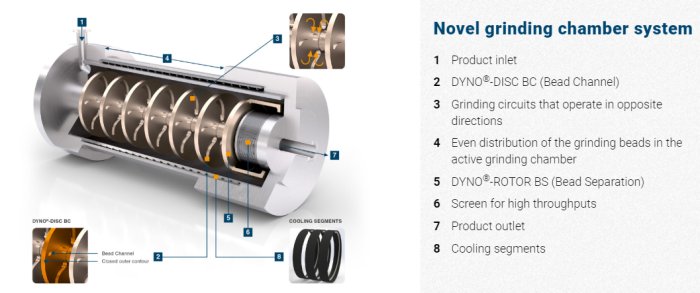

WAB-GROUP brings over six decades of excellence in grinding and dispersion technology with their latest innovation, the DYNO-MILL Universal Bead Mill (UBM). This state-of-the-art agitator bead mill is designed with advanced features to handle the full range of dispersion and ultra-fine grinding applications, from small laboratory batches to large-scale industrial production. The DYNO-DISC BC agitator discs within the mill boast unique grinding media channels that ensure efficient media acceleration and create dual grinding circuits operating in opposing directions for optimal grinding. The machine's ergonomic design includes a grinding chamber at an ideal working height, facilitating easy cleaning and maintenance, thus minimizing downtime. The high durability of the components extends maintenance intervals, significantly cutting down on maintenance costs. WAB-GROUP's commitment to tailored solutions is evident in their customization options, including specialized models like the DYNO-MILL Pharma, meeting the diverse needs of advanced engineering projects.Over 60 years of experience and leading technologies combined in one series: DYNO-MILL Universal Bead Mill (UBM).

The new generation of WAB-GROUP agitator bead mill covers the entire range from dispersion to ultra-fine grinding of small product quantities in the laboratory to the production of large quantities. The machine series meets the requirements of the industry in terms of efficiency, reliability and operating costs.

The latest generation of DYNO-DISC BC agitator discs have been specially developed for this series. They are characterized by unique grinding media channels and a closed outer contour. The grinding media channels ensure efficient acceleration of the grinding media along a precisely defined path. During operation, each of the grinding media channels creates two efficient grinding circuits between the DYNO-DISC BC agitator discs, which operate in opposite directions.

The grinding chamber is at an ideal working height and allows quick and ergonomic cleaning operations. After opening, the grinding media are emptied into a robust stainless steel channel firmly connected to the machine housing. From there, they can be conveniently filled into other containers.

The high wear resistance of the DYNO-MILL UBM extends maintenance cycles and thus reduces maintenance costs. Together with the unbeatable WAB-GROUP machine service, this mill generation achieves high machine availability!

- Suitability for high throughputs and highly viscous products due to large screen passage areas

- Long screen life

- Sieve change possible without opening the grinding chamber

- Suitability for passage and circuit operation

- Wide variety of materials to choose the optimal machine equipment

- Use of ø 0.2-2.5 mm grinding media

- Grinding chamber volume from 0.5-100 l

- Low-maintenance, double-acting mechanical seal for highest demands

- Closed machine housing

- Low noise level

- Wide range of control solutions