5 products found

Willy A. Bachofen AG products

Grinding & Dispersion Technology

Dyno - Model Mill Uni Lab - Laboratory Agitator Bead Mill

The DYNO-MILL UNI LAB is designed to meet the rigorous demands of research and development. This compact laboratory agitator bead mill incorporates DYNO-MILL UBM and ECM-AP technology, making it an ideal solution for producing dispersions and fine grinds down to the nanometer range. It can handle a wide range of product viscosities with its dual grinding principles and unique DYNO-ACCELERATOR technology, which optimizes flexibility and cost-effectiveness. This model features DYNO-DISC BC agitator discs with specialized grinding media channels that ensure efficient acceleration and effective grinding by creating two counter-rotating circuits. The DYNO-MILL UNI LAB is engineered for easy integration into laboratory settings, providing reliable performance for industries such as pharmaceuticals, coatings, and cosmetics, where precise particle size control is critical.

Dyno - Model Mill Ubm - Universal Agitator Bead Mill

WAB-GROUP brings over six decades of excellence in grinding and dispersion technology with their latest innovation, the DYNO-MILL Universal Bead Mill (UBM). This state-of-the-art agitator bead mill is designed with advanced features to handle the full range of dispersion and ultra-fine grinding applications, from small laboratory batches to large-scale industrial production. The DYNO-DISC BC agitator discs within the mill boast unique grinding media channels that ensure efficient media acceleration and create dual grinding circuits operating in opposing directions for optimal grinding. The machine's ergonomic design includes a grinding chamber at an ideal working height, facilitating easy cleaning and maintenance, thus minimizing downtime. The high durability of the components extends maintenance intervals, significantly cutting down on maintenance costs. WAB-GROUP's commitment to tailored solutions is evident in their customization options, including specialized models like the DYNO-MILL Pharma, meeting the diverse needs of advanced engineering projects.Mixing Technology

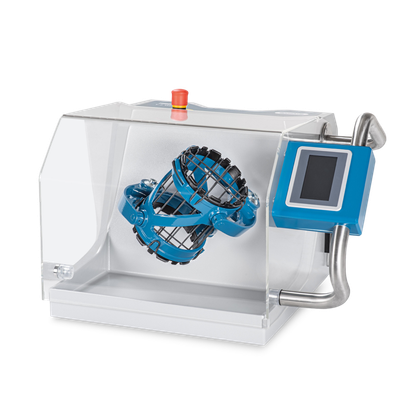

Turbula - 3D Shaker Mixer

The TURBULA 3D shaker mixer from WAB-GROUP is a highly efficient mixing solution designed for container volumes ranging from 0.1 to 55 liters. Utilized in a wide array of industries including pharmaceuticals, cosmetics, food & beverage, and chemicals, the TURBULA stands out for its superb homogeneity and reproducibility. The mixing process is contamination-free, thanks to the closed mixing vessel. The mixer's effectiveness is due to its unique motion combining rotation, translation, and inversion, which results in a constantly changing pulsating state that ensures optimal mixing in the shortest time. Its user-friendly interface includes an intuitive touchscreen control panel, allowing for speed adjustments and the saving of specific mixing recipes. Additionally, the TURBULA mixers can adapt to various container sizes and types, further enhancing their versatility. These features make TURBULA mixers indispensable for achieving high-quality results, particularly in laboratory and production settings.

Dyna-MIX - 3D Shaker Mixer

The dyna-MIX 3D shaker mixer by WAB-GROUP is designed for homogeneous mixing of solids, solids with liquids, and liquids within tank volumes ranging from 40 to 1000 liters. This robust machine ensures precise mixing of larger material quantities with high specific weights while maintaining high-quality mixing results. The system uses a patented three-dimensional motion, meticulously controlled via its programmable control module. This system guarantees reproducibility and exceptional homogeneity in mixing processes. The mixer’s container is securely clamped, with customization options available to meet specific requirements. Applications include various industries such as pharmaceuticals, cosmetics, battery materials, and more. Customers can expect technical support with local sites and specialists available for consultation.Flow Chemistry

Wab IMPA°CT Reactor - Mechanochemical Reactor

The WAB IMPA°CT REACTOR represents the pinnacle of innovation in the realm of flow chemistry and mechanochemistry. Functioning as an inductively heated mechanochemistry reactor, it allows for continuous chemical reactions by heating reactants directly up to an impressive +160°C. Capable of transforming traditional batch processes into continuous ones, it offers a groundbreaking application for molecular synthesis through mechanochemistry, ensuring rapid and selective reactions along with the option to scale from grams per hour to tons per hour. By incorporating horizontal reaction chambers and high-tech induction heating around stirring elements, it efficiently facilitates material transport and activation. This reactor suits various substances including liquids, viscous and pumpable products, and heterogeneous catalysts. It combines three impact technologies in one unit, ensuring uniform mechanical energy input and renewing reactant surfaces consistently. Suitable for exothermic and endothermic processes, it’s ideal for cost reduction through process intensification and minimizing ecological impact. The WAB IMPA°CT REACTOR is highly versatile, evidenced by its applications in synthesizing compounds like Solketal and Zinc Monoglycerolate, crucial in industries like pharmaceuticals and plastics.