- Home

- Companies

- Shanghai Techase Environment Protection ...

- Products

- Elaspress Super - Model TCYZ - High ...

Elaspress Super - Model TCYZ -High Pressure Filter Press

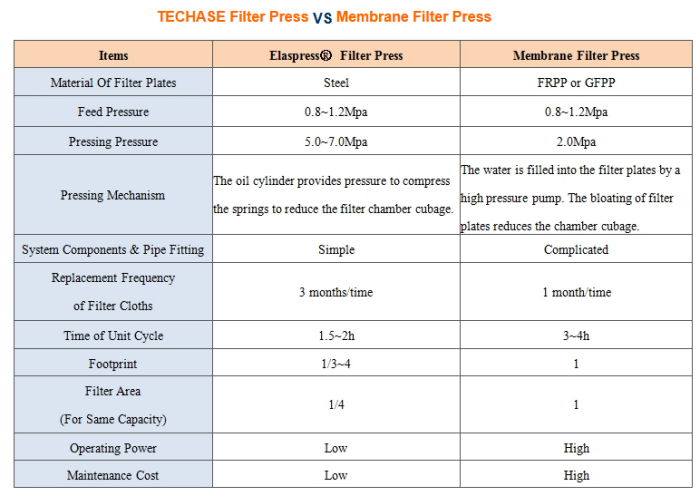

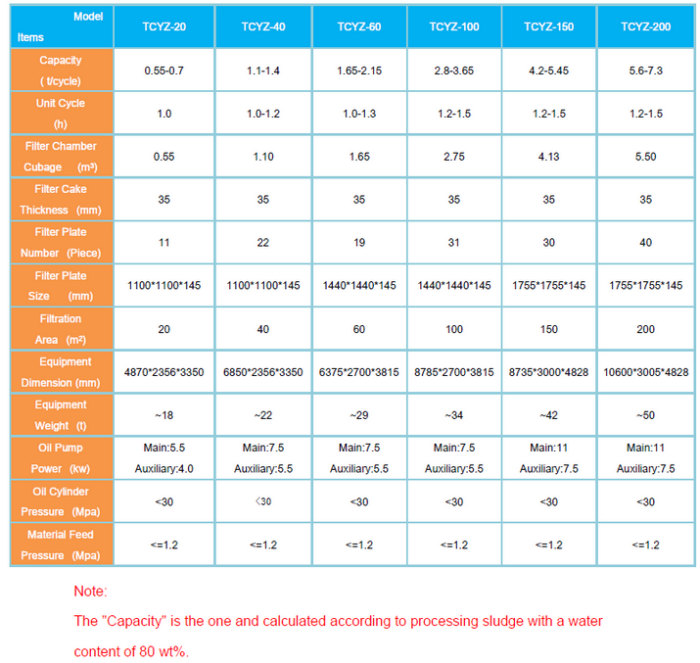

Elaspress Super-high Pressure Filter Press, which was developed by Techase in cooperation with Tongji University based on extensive R&D to meet customers’ requirements, is a new innovative pressure filter that is supplied for a wide range of applications in municipal & industrial industries to generate filter cakes whose dryness which, depending on the fitered materials, can even reach 80% (20% humidity) under pressure.

- Higher Compression Ratio

- Larger Filtration Area

- 1/4 Filter Cloths

- Less Associated Devices

- Filter Plates Made of Steel, Instead of Fragile PP

Techase have optimized the structure of the conventional filter presses and ingeniously applied elastic medias of stainless steel to creat pressure and reduce energy consumption. Owing to its design and innovation, when compared with other similar filter presses, Elaspress® Super-high Pressure Filter Press is considered of higher efficiency, smaller footprint, lower operational cost, higher performance and easier operation & maintenance.

- Skeleton

- Filter Pack: filter plates made of steel fitted with filter cloths, springs of stainless steel

- Automatic Plates Shifting System

- Movable Drip Tray

- Hydraulic System

- Control Cabinet

- Automatic Discharge

- Automatic Cloths Cleaning

- PLC Remote Control

- Belt / Screw Converyor

Higher Compression Ratio

The elastic media applied by the filter press have higher compression ratio compared with the membrane filter presses. Then the feeding load is greatly eased and the filtration time cycle is well shortened.

Larger Filtration Area

With same area`s filter cloths, Elaspress Filter Press has larger effective filtration area when compared with other types of filter presses.

1/4 Filter Cloths

For same capacity, the Elaspress Filter Presses only use 1/4 filter cloths of other types of filter presses so that significant cloths replacement cost is saved.

3 Times Pressing Pressure

The pressure provided by the hydraulic oil cylinder for second time`s pressing is as high as 5~7Mpa.

4 Times Efficiency

The unit filtration time cycle of this new filter press is 1.0~1.5 hours, only 1/4 of the traditional ones.

Less Associated Devices

Elaspress Filter Presses only use a hydraulic oil cylinder to provide enough pressure when other types of filter presses have to be equipped with water tanks, air compressors, water pumps, compression pumps, air storage tanks and other necessary devices.

Filter Plates Made of Steel, Instead of Fragile PP

For the filter plates of Elaspress Filter Presses are made of steel and hard to be damaged, they can be used for 5~8 years without any replacement.