- Home

- Companies

- Electric H2O, Inc.

- Products

- Electric H2O - Sweeper Jet Systems

Electric H2O - Sweeper Jet Systems

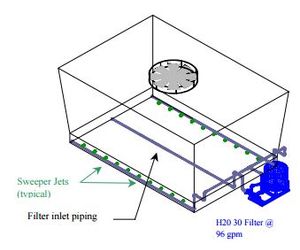

Electric H2O, Inc. introduces the newest sweeper jet designed specifically for cooling tower basins. In order for cooling tower filters to do an effective job removing solid contaminants from the cooling tower basin, the solid particulates must be directed toward the filter inlet. Electric H2O’s Sweeper Jet nozzles achieve this through a uniquely designed elliptical discharge outlet that directs basin water toward the filter inlet in a flat fan pattern. This maximizes the performance of any cooling tower filtration system by actively sending particulates and sedimentation from stagnation zones in the tower sump to the filter.

Using the venturi principle, Sweeper Jets create a negative pressure region at the nozzle outlet, thereby forcing water into the elliptical discharge. This permits the use of a smaller pump to deliver the volume of water required for effective sweeping of solids to the filter inlet. The elliptical pattern sweeps a large path width, achieving a significant reduction in stagnant areas between nozzles.

Sweeper Jets are installed into a pipe that runs along the cooling tower basin bottom. Clamp-on swivel mounts are available to direct the sweeping path into hard-to-reach areas and to accommodate irregularly shaped basins. Electric H2O provides sweeper jet systems tailored to each application. Basin size and shape, liquid depth, competing flow characteristics, solids loading and other site-specific criteria are examined for optimal flow and cleaning results. From there, Electric H2O engineers determine the correct sweeper jet size, quantity and placement.

Sweeper Jet Selection Criteria

For effective solids sweeping to the filter inlet piping, typically allow one gallon per minute of flow to the sweeper jets for every one square foot of cooling tower basin area. Sweeper jet spacing is typically 8 to 10 inches.

- Example: Basin area = 96 ft2

- 96 ft2 x 1 gpm/ft2 = 96 gpm to sweeper jet nozzles.

- For SJ-250 sweeper jet rated at 5 gpm, 96 gpm/5 gpm per nozzle = 20 nozzles.

- For SJ-375 sweeper jet rated at 8 gpm, 96 gpm/8 gpm per nozzle = 12 nozzles.