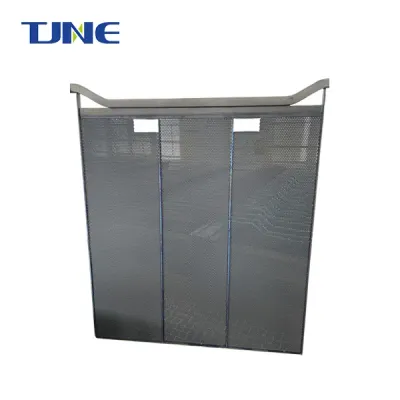

TJNE - Electrodeposited Titanium Electrode for Zinc Electroplating

Product Overview: It has good electrical conductivity, combined with the high strength and corrosion resistance of industrial pure titanium, to prepare a new titanium-based lead dioxide anode.

The titanium-based lead dioxide anode developed by Taijin Company can replace pure lead anode, lead-tin, or lead-antimony alloy anode, and precious metal anode in the field of hydrometallurgy.

Product features: corrosion resistance, minimal lead dissolution, good electrical conductivity, and the ability to pass large currents.

Product advantages: Compared with traditional lead anodes, it can increase by 2%, reduce lead dissolution rate by 99%, extend service life, and reduce costs.

Application conditions: PH<4, sulfuric acid<500g/L, temperature<80℃, F-<20ppm, Cl-<50ppm, Ca<50ppm, Mg<50ppm, Mn<1ppm, oil content<3ppm, H2O2<1ppm.

Application areas: electrolytic nickel, electrolytic zinc, electrolytic copper.

The electrodeposited titanium electrode for zinc is a high-quality electrode used in various electrochemical applications. It is designed to provide excellent performance and durability, making it suitable for demanding industrial and commercial applications.

The electrode is made from high-quality titanium material, which offers superior corrosion resistance and electrical conductivity. It is specifically designed for zinc electroplating processes, ensuring efficient and reliable zinc deposition on the substrate surface.

The electrode works based on the principle of electrodeposition, where an electric current is passed through the electrode, causing the zinc ions in the plating solution to be reduced and deposited onto the substrate surface. This electrode offers excellent chemical compatibility, ensuring stable and uniform zinc plating results.