- Home

- Companies

- Ekogrid Oy

- Products

- Ekogrid - Electrokinetic Field ...

Ekogrid - Electrokinetic Field Technology for Soil Remediation

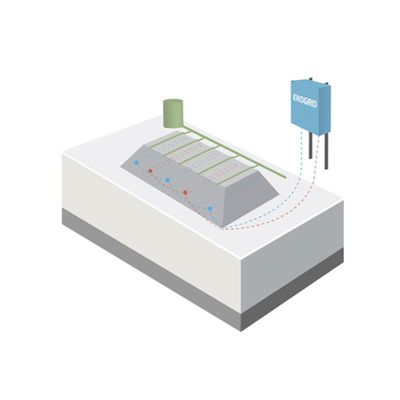

EKOGRID technology can be installed almost anywhere. EKOGRID is effective for the treatment of soil after it has been excavated. This treatment can be done on-site, ex situ at a treatment center and/or using: Biopiles Biocells Biocontainers The customized electrokinetic field is created using a series of steel electrodes that are set at intervals and installed in the excavated soil to be treated.

Electrode spacing is typically five meters apart. The system is extremely scalable and flexible. A demo project may include only nine electrodes, whereas with larger projects several EKOGRID™ control units can be combined to treat large areas in excess of hundreds of thousands of cubic meters.

Electrodes can also be installed at an angle or horizontally inside the piles to be treated or inside closed containers.

The installation depth is only limited by the installation technologies available. Electrodes will reach the depth and width of the polluted soil.

Because of the low operating voltage and very low current densities applied, the system will not cause any hazard or danger to humans or animals at the site.

The low energy consumption also allows the use of alternative energy sources, such as solar panels or wind turbines, backed up with batteries and diesel generators, for example.

- EKOGRID™ control unit,

- Electrical connection or alternative energy source,

- Electrodes installed to the depth of contamination to be treated,

- Cables and connections,

- Software,

- Know-how of the EKOGRID™ experts,

- Combination with other solutions which is typically optimized by local partners in each market as they have the knowledge if the local offering.

EKOGRID is an electrokinetic method that utilizes natural well-known phenomena and reactions:

- Electro-osmosis, electrophoresis and electromigration,

- Electrochemical redox reactions (e.g. electrolysis),

- Bioremediation processes, increased microbial activity.

The core of this unique system:

- Optimized pulsed voltage output,

- Frequently changing polarity of the output:

- This makes the charged contents of the pore water move quickly back and forth (short electro-osmotic pulses) so that freshly formed free radicals and oxygen that promote the oxidization of compounds emerge.

- The system uses the capacitive nature of the matrix (soil), thus enabling it to work at a very low output voltage.

- Reactions will occur at the surface of each soil particle and evenly spread throughout the whole matrix and precisely where the pollution is. The finer the soil grain size, the more effectively the system operates due to faster and more complete remediation.

EKOGRIDTM patented products and technologies are cost-effective, simple to install, and safe to use both for the operators and the environment.

With the correct settings made in the commissioning phase, our system utilizes the capacitive nature of the soil matrix. Reactions will occur at the surface of each soil particle, precisely where the pollution is and everywhere between the electrodes -not just at the installed electrodes. As a result, no energy will be wasted and the system will consume extremely low levels of energy. The effect can be quickly seen in the form of reduced pollutant concentrations in the soil and groundwater as well as stabilized ORP and dissolved oxygen levels.

- Continuous and sustained degradation of target compounds

- Easy to install with relatively low related costs

- Works on soil, groundwater and sediments, and especially well in low-permeable soils such as clays, silts and fine sands

- Enhances in situ degradation of broad range of organic contaminants

- Intelligent system based on natural phenomena,

- No secondary pollution from noise, gas or particle pollution,

- Low power consumption and very little resources needed for operations and maintenance,

- No hazardous chemicals needed,

- No harm to fauna or wildlife,

- Alternative/renewable energy source-compatible,

- Simple logistics and work safety: in situ treatment requires no transport and thus can be carried out discreetly. There is no need for personnel to be on site except during installation, dismantling, and measurement sampling.

- Enhances bioremediation

- Groundwater aquifers are treated simultaneously with soil

The technology has proven to work on a substantially wide range of organic pollutants in the ground, ground water and bottom sediments, including:

- Aliphatic hydrocarbons (gasoline, petrol, diesel, heavy oil)

- Benzene, toluene, ethylbenzene, xylenes (BTEX compounds), MTBE, ETBE and TBA

- Polycyclic aromatic hydrocarbons (PAHs)

- Chlorophenols

- Chloroethenes (TeCE, TCE, DCEs and MCE)