- Home

- Companies

- Pressure Control Solutions (PCS)

- Products

- PCS - Model ERC Series - Electronic ...

PCS - Model ERC Series -Electronic Pressure Controllers

ERC stands for Electronic Reference pressure Control. Although the instrument is well suited to be used as a straightforward pressure reducing – or back pressure controller, it offers much more: This product line was specifically designed by PCS to set the reference pressure for dome-loaded back pressure regulators – very precisely! – for pressures ranging from vacuum up to 200 bar gauge.

Unique design

Controllers in our ERC Series contain a pressure sensor, a proportional valve, and a flow restrictor, all in 1 unique and compact design, combined with a sophisticated PID controller that actuates the proportional valve based on the pressure sensor signal. In a stable situation, the control valve continuously controls the desired pressure by bleeding a tiny amount of reference gas.

Available configurations: Fail-safe modes

By placing the flow restrictor upstream or downstream of the proportional valve, the instrument can be configured to “full pressure” or “pressure release” in case of a power failure. This results in either normally closed, or normally opened control when applying an Equilibar dome loaded back pressure controller.

These electronic pressure controllers facilitate high safety standards in your process. With the pressure release configuration, controlled depressurization is inherent to this product design (dp/dt decreases during depressurization). Safe venting of chemicals is ensured by means of a (centralized) captured vent.

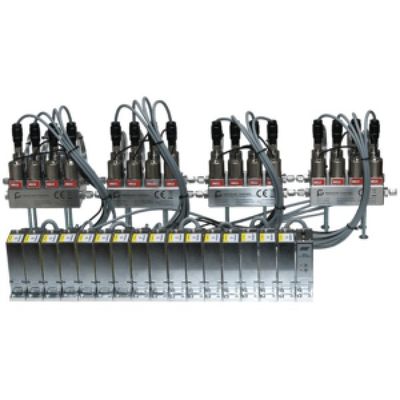

Available models: 1, 2 or 4-channel models

We offer multiple models, suitable for 1, 2, and 4-channel set-ups with 1 central inlet and (centralized) captured vent. The ERC Series controllers offer a turndown ratio in pressure control of 1:100 with excellent control stability and reproducibility.

We refer to the specifications tab on the left side of this page for more details!

How PCS came to solve customer needs for electronic precision process control

Process engineers and researchers all over the world are more and more familiar with Equilibar® dome-loaded back pressure regulators. The robust design, excellent performance and wide operating range are fully adopted by the industry. In a response to customer needs and frequently asked questions, PCS developed its own electronic pressure controller. This initial design regarded the multi-channel electronic reference controller, enabling automated control of reactor pressure in high-throughput-multi-reactor-systems, using Equilibar technology – driven by the needs of European catalysis researchers that turned to Pressure Control Solutions for help in solving challenges that no existing product could solve. See also this blog on catalyst research.

Soon after this was launched, it became clear that researchers and engineers in other areas of expertise had similar needs. Electronic control options for their Equilibar regulators were much desirable also in other applications outside catalysis. Pressure Control Solutions therefore continued its development, resulting in the ERC Series: Electronic (reference) pressure controllers available in a 1-, 2 and 4-channel version for a wide range of applications. Meanwhile, we have also applied the ERC Series successfully in process applications that don’t include a back pressure regulator. We can safely state now that the ERC Series has become one of the most successful product innovations by Pressure Control Solutions.

So although originally intended for electronic reference control, this instrument now has a proven track record for many other applications. Whether combined with an Equilibar® back pressure regulator or not, an electronic pressure controller in the ERC Series enables stability and repeatability that is unparalleled in precision pressure control. Watch the video below for a further introduction.

How this electronic reference pressure controller (ERC) is built up

The basis of the ERC is a 1-, 2- or 4-channel manifold, containing one centralized input and output. The units can even be connected to create an 8-, 12-, … up to 96-channel controller!

A high precision pressure sensor monitors the process pressure and is connected to a PID-controller. The PID-controller controls the proportional valve that will increase or decrease the process pressure when needed. The flow is restricted by means of a high precision capillary, that is selected based on process requirements to optimize the ratio between consumption of reference gas and control speed. This flow restrictor can be easily replaced to adapt consumption and control speed of the application. As a user, you can limit the flow consumption to 0…30 mln/min under nominal conditions. Depending on the chosen sensor, the ERC unit is capable of a control range between -1…200 bar gauge.

As process engineer, you set the desired pressure by means of an analog signal or, optionally, a digital control system of your choice. Options include DeviceNet, ProfiBus, ProfiNet, Ethercat , FlowBus, ModBus RTU, ModBus TCP/IP, CANopen. All this results in a pressure controller with an unparalelled control stability of 0.01% and a repeatability of 0.02%, or better!

Facilitating safety

Although Equilibar back pressure regulators are equipped with a diaphragm that can withstand 4 times the maximum allowable working pressure, the harsh conditions that a back pressure regulator needs to withstand can cause damage to it. This could eventually lead to process media escaping through the reference port of the dome loaded regulator. Therefore, in the multichannel design, we capture the outlet of the flow restrictors to one central outlet that you can connect to the waste of your system. You can direct the media coming from your reactor safely to the vent of your system.

Example applications

The ERC Series can be used in a wide variety of applications: From vacuum applications to process lines for challenging fluids and precision pressure applications up to 200 bar – thanks to its versatility and broad customization options, the ERC Series can do it all. Presented here are examples of applications in which the ERC has been successfully applied.

- Catalytic Research

- Controlled Depressurization

- High Pressure Calibration

- Vacuum Plasma Control

- Vacuum Distillation

- Altitude simulation

- Safely vent chemicals by means of (centralized) Captured Vent

- High Accuracy Sensor Calibration Chamber

- High Precision Control Ink Reservoir

This ERC Series is truly an all-rounder, so there are many more possibilities! Are you interested to find out what the ERC Series can do for you? Contact us for direct advice and expertise!