Tekran - Model 3310Xi for 3300Xi HgCEMS -Elemental Mercury Calibration Unit

The Tekran® 3300Xi HgCEMS includes an integrated, NIST traceable, elemental mercury generator for routine calibration through the entire system, by injecting gas in front of the probe filter. For regulatory monitoring requiring additional calibration resources, Tekran offers the Model 3310Xi Calibrator which is designed to seamlessly plug into the Model 3300Xi HgCEMS cabinet. The 3310Xi Calibrator will generate known elemental mercury concentrations using a NIST traceable, temperature controlled, saturated mercury vapor source. Precision mass flow controllers dilute the source output to the desired value. The Model 3310Xi Calibrator includes a host of advanced features that provide superior accuracy and allow unattended, remote operation. For more information and a full listing of specifications, please download the fact sheet by clicking on the 3310Xi image at the right.

Model 3310Xi Calibrators can be supplied certified, with mercury outputs traceable to NIST.

- Output concentration range: 0.5 – 1300 μg/m3

- Calibration gas delivery rate: 2 – 30 SLPM

- Hg source control range: 4.00 to 40.00 °C

- Mercury source will last for many years

The Tekran® Model 3310Xi Elemental Mercury Calibrator allows high level mercury monitoring systems to be accurately calibrated using elemental mercury. It integrates seamlessly with the Tekran® Series 3300Xi speciating CEM, however it can also be used as a stand-alone mercury calibration system. The calibration source allows both multi-point calibrations and standard additions to be automatically initiated. The unit generates concentrations of mercury by using a NIST traceable temperature controlled saturated mercury vapor source. Precision mass flow controllers are used to dilute the output of this source to the desired value. The unit is capable of continuously generating large flow rates of calibration gas at virtually no ongoing cost - unlike expensive mercury calibration gas cylinders.

The Model 3310Xi incorporates technology originally developed for the Model 2505 Manual Calibration Unit. Unlike other saturated sources, the Model 3310Xi contains a host of advanced features that provide superior accuracy and allow unattended, remote operation.

- Output concentration range: 0.5-1300 ug/m3 *

- Calibration gas delivery rate: 2-30 SLPM *

- Mercury source will last for many years

- Allowable ambient temp: +5 to +40 °C

- Hg source control range: +4.00 to +40.001 °C

- Independent linearization tables for each MFC

- Coal fired power plants

- Waste incinerators

- Other industrial sources

- Speciation studies

- Bench scale testing

- Mercury removal process monitoring

* Standard Unit. Other working ranges are available. Not all output flow/concentration combinations are available simultaneously. Contact Tekran for details.

1 Other temperature ranges available.

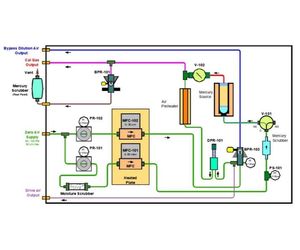

A Peltier heater/cooler maintains a precise temperature for the mercury reservoir. A mass flow controller (MFC101) provides a precise and accurate carrier flow through the mercury chamber. The emerging air is saturated with elemental mercury vapor. This saturated flow is diluted with MFC-102. Solenoid valves serve to positively isolate the source when mercury is not required and to select between two available outputs. Backpressure regulators provide positive pressure relief in case either output is activated while blocked. The MFC’s are heated to minimize thermal drift. Additional heated zones and safety interlocks ensure that the source is activated only when all temperatures are stable.

- Three output ports:

- Calibration Gas Output

- Bypass Dilution Air

- Drive Air

- High Output rate: up to 30 SLPM

- Heated/cooled saturated mercury source

- Ultra-precise source control

- Repeatability: ±0.02°C

- Accuracy: ±0.05°C

- Range: +4.00 - +40.001 °C

- Automatic purging of system lines after high value calibrations are complete or if error is detected during operation

- Precision pressure sensor allows constant output concentration despite back pressure variations

- MFC’s are temperature controlled to minimize thermal drift

- MFC’s are individually calibrated to minimize errors at low flow settings

- Multi-point calibration tables

- Linear interpolation between calibration points

- Solenoid valves provide the following functions:

- Isolation of Hg source until safe to activate

All Calibrators can be used as an integrated part of the Series 3300Xi CEM. Communication with the module via industry-standard RS-485 Modbus-RTU protocol (USB to RS-485 converter is supplied with each system). For stand alone applications, a Windows™ based program provides direct communication & control of the module and provides the calibration unit with a wealth of capabilities.

- Readout and logging of all current temperatures, pressures, and flows

- Setting of all temperatures and MFC set points

- Calculation, display and logging of current output concentration (at any desired reference conditions)

- Initiation of immediate calibration operation

- Initiation of automatic scheduled or “on demand” multi-step calibration sequences

- Periodic temperature sensor and MFC recalibrations

Control via computer GUI, electrical contact closures or dde link from other PC applications (e.g. Excel)

- Output log files are available in standard CSV format.

- Optional: Calibrator PC can act as an OPC server for use with SCADA systems

- Optional: Calibrator PC can act as Modbus or Modbus/TCP-IP slave.