- Home

- Companies

- Promeco SpA

- Products

- Promeco - Emergency Shelter

Promeco - Emergency Shelter

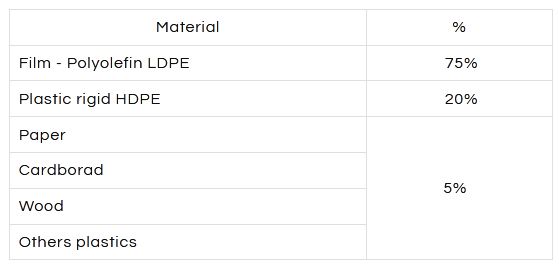

Input waste: Mixed plastic (min. 75%) and others contaminants.

- profiles boards made of recycled plastic

The plant designed by Promeco allows the conversion of plastic waste to profiles that can be assembled to build other products, such as the emergency living units.

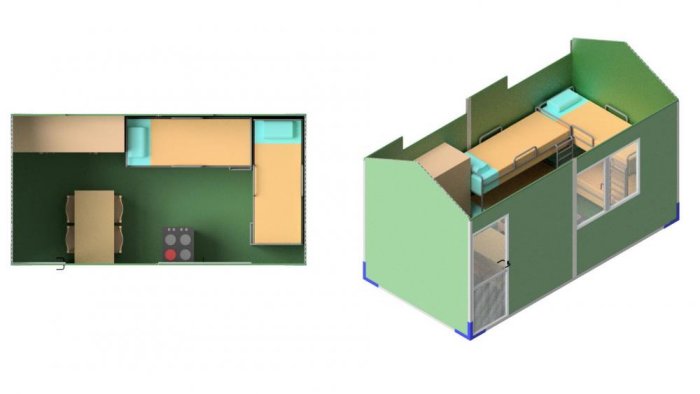

Easy and fast to assemble, reliable and safe to live in, Promeco has engineered a complete turnkey plant designed to manufacture with plastic waste economical standard living units ideal in any emergency situation when immediate housing is required.

- Sides (walls): 5,30 x 2,65 m

- Height: 2,76 m

- Floor area: 14 sqm

- Total weight: 1.100 kg

- Total volume in pallet: mc 2,70

This projects aims to build low cost housing from recycled material, namely mixed waste plastic, with the following features:

- Requires limited storage space

- Extremely easy to assemble

- Ready for immediate use

- Easy to transport

- Environmental friendly

These living units may be used as shelters for people in case of natural disasters such as floods, tsunami, earthquakes, hurricanes or in UNHCR refugee camps.

The shelters manufactured with Promeco’s plants are designed to provide housing in all post disaster settings and in extreme climates they can be further increased with appropriate insulation. Their floorspace can comfortably host up to 4 people.

This is the reliable and long lasting alternative for the 3,5 million people still living in tents worldwide.

Profiles boards made of recycled plastic

Dimensions: width 300 mm, length 2.650 mm, thickness 30 mm with tongue and groove joints and honey comb structure

- Capacity per line: 500 kg/hour

- Total houses per year: no. 2.300

- equivalent to shelter for 9.200 people

- Total floor surface for storage: 1.500 sqm

- Total floor surface per year: 28.000 sqm