- Home

- Companies

- Dragon Water Technologies Ltd (DWT)

- Products

- Encore - Model ED - Solenoid Diaphragm ...

Encore - Model ED -Solenoid Diaphragm Dosing Pump

Reliable Dosing of Chemicals: Solenoid diaphragm dosing pumps play an important role in the reliable and accurate dosing of liquids. The Encore® ED line of solenoid driven metering pumps are specifically designed for water treatment and the process industry.

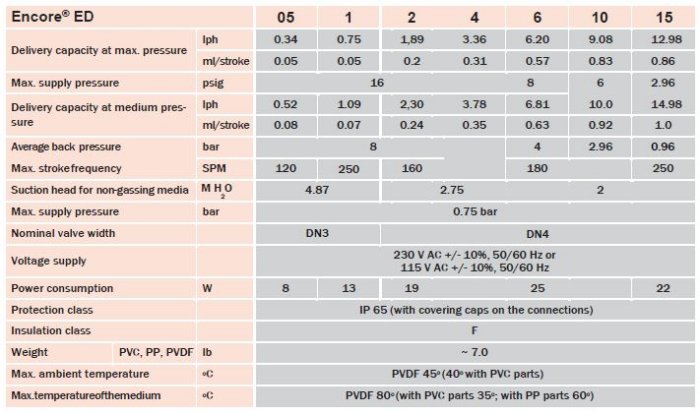

The Encore ED is available in seven sizes for metering applications ranging to 14.98 lph with back pressures up to 16 bar. Double-ball valves ensure accurate, consistent dosing. To adapt the dosing performance, the stroke frequency can be adjusted manually or via an external control contact. You can thus dose with a flick of the wrist.

Several different materials and connections are available for suction and discharge side, depending on the specific applications. By using appropriate and recommended materials, the Encore can be used in a wide variety of process applications.

Matching accessory sets with hoses, injection nozzles and suction lines allow quick installation and reliable operation.

- Thanks to the sturdy, low-maintenance solenoid drive, the media being supplied (for example acids, alkalis, coagulants and flocculants) is reliably and accurately dosed.

- The combination of the Encore ED’s solid design and the easy-to-use digital controls allow for short set up times and efficient operation.

- The compact design and the small footprint allow for easy integration into dosing systems even for installations with limited space available.

- Wall mounting is possible provided the check valves remain in a vertical orientation by rotating the head.

- Capacity range to 14.98 lph, up to 16 bar

- Power supply 230 VAC +/- 10%, 50/60 Hz, IP 65, max. 25 W or 115 VAC +/-10%, 50/60 Hz, IP 65, max. 25 W

- Graphical display

- Materials available: PVC, PP and PVDF

- Material consistency for the pumps and accessories

- Dosing head manual venting

- Wall and floor mounting

- Double-ball valves ensure accurate dosing

- Precise pump settings using the keypad

- External control via floating contacts with impulse increase and reduction

- Level input with early warning and main alarm Release input

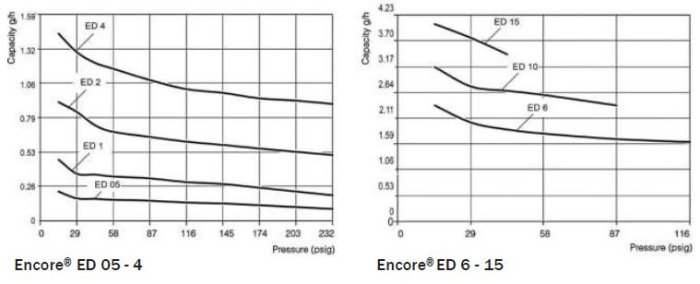

The flow curves are valid for ambient temperatures of 20°C (68°F) and dosing water at 100% stroke frequency. The delivery capacities depend on the medium (density and viscosity) and temperature.

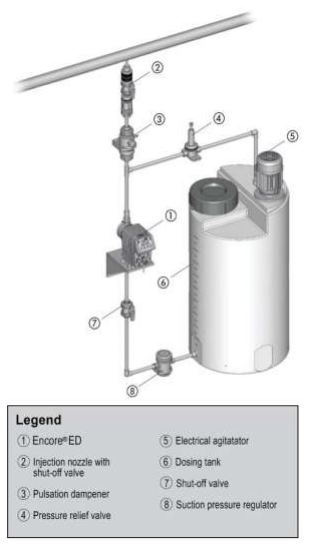

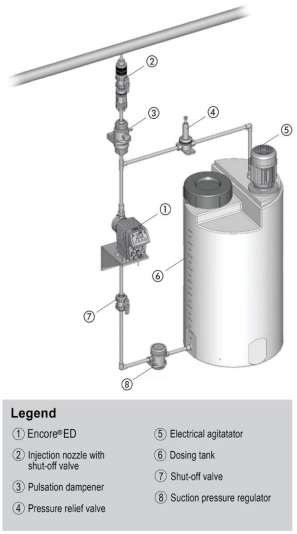

Even the best pump can be improved – simply by the addition of appropriate accessories.

Suitable sets of accessories, consisting of suction/ discharge tubing, foot valve and injection nozzle, are available for the dosing pumps.

To turn your dosing pump into an efficient dosing system, we recommend using the following accessories:

- Injection nozzles - to dose the medium into the main line and to prevent it from flowing back into the pressure line

- Back pressure and pressure relief valves - to increase dosing accuracy or to protect the system against excessive pressure

- Pulsation dampener - to dampen supply flow as well as to reduce discharge flow pulsations

- Priming aids - to significantly ease priming of dosing pumps with low supply volumes per stroke, for large suction heights, highly viscous dosing media, for initial priming or when priming after the system has been idle

- Suction pressure regulator - to prevent medium flow when the dosing pump is not running or to prevent a vacuum being formed in the event of a pipe failure

Even the best pump can be improved – simply by the addition of appropriate accessories.

Suitable sets of accessories, consisting of suction/discharge tubing, foot valve and injection nozzle, are available for the dosing pumps.

To turn your dosing pump into an efficient dosing system, we recommend using the following accessories:

- Injection nozzles - to dose the medium into the main line and to prevent it from flowing back into the pressure line

- Back pressure and pressure relief valves – to increase dosing accuracy or to protect the system against excessive pressure

- Pulsation dampener - to dampen supply flow as well as to reduce discharge flow pulsations

- Priming aids - to significantly ease priming of dosing pumps with low supply volumes per stroke, for large suction heights, highly viscous dosing media, for initial priming or when priming after the system has been idle

- Suction pressure regulator -to prevent medium flow when the dosing pump is not running or to prevent a vacuum being formed in the event of a pipe failure