- Home

- Companies

- Hidrostal Holding AG

- Products

- Hidrostal - End Suction Pumps / Bearing ...

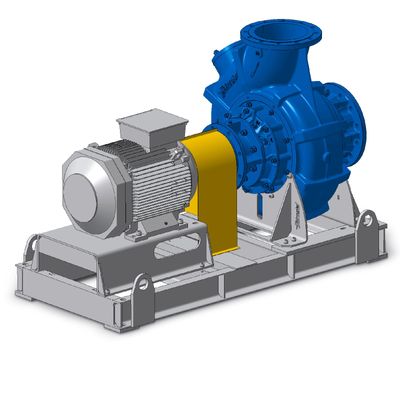

Hidrostal - End Suction Pumps / Bearing Frame Pumps

A range of versatile, energy efficient bearing frame pumps, suitable for horizontal or vertical mounting and incorporating the Hidrostal Screw Centrifugal Impeller.

Hidrostal offers three distinct end suction pump designs. All designs are suitable for horizontal or vertical mounting.

Direct Coupled End Suction Pump

The direct flange mounted motor is spigoted onto the bearing frame and eliminates the possibility of shaft misalignment. As additional security, a flexible coupling is also employed. The units are suitable for horizontal and vertical mounting and the back pull out design means the complete rotating unit, including the motor, can be simply withdrawn for inspection and maintenance of the hydraulic end. Available for pumps with dischange sizes of 50 to 700 mm (2 to 28").

Close Coupled End Suction Pump

The close coupled end suction bearing frames are identical to the direct coupled ones but with a free shaft end. The units are suitable for horizontal and vertical mounting. Available for pumps with dischange sizes of 50 to 700 mm (2 to 28").

Long Coupled End Suction Pump

The long coupled end suction pumps are of a traditional design, offering robust construction and long reliable service for both vertical and horizontal mounting. The standard construction has grease lubricated bearings, and oil lubrication can be provided on horizontal units to meet the requirements of process industries. The bearing housing is of modular construction, permitting various arrangements of mechanical seals to be used. The shaft end bearings have been selected to be used with belt drives and yet maintain long bearing lives.

- Industrial effluent

- Raw unscreened sewage

- Viscous sludge

- Return activated sludge

- Drainage and storm water

- Process waste

- Sump cleanup

- Bacterial floc

- Live fish

- Fruits and vegetables

- Direct access to the pump and to the instrumentation

- Maintenance in a clean environment

- Commercially-available drive elements can be used

- Robust construction for smooth operation

- Back pull-out design means the complete rotating unit can be simply withdrawn for inspection and maintenance of the hydraulic end

- Heavy duty bearings for superior L-10 bearing life in both direct or belt driven applications

- Discharge Sizes: 32 - 700 mm (1.5 - 28")

- Suction Sizes: 32 - 700 mm (1.5 - 28")

- Head: 0.5 - 90 m (2- 300 ft)

- Flow: 0.5 - 3000 l/s (7 - 47500 gpm)

- Power: 0.1 - 650 kW (0.1 - 870 HP)

- Frequencies: 50 Hz, 60 Hz, VFD

- Materials: Cast Iron, Ductile Iron, Hi-Chrome, Stainless Steel, Duplex