- Home

- Companies

- Focus Laboratories Inc.

- Products

- Focus - Endotoxin

Focus - Endotoxin

If the device is rinsed with water at any point in the manufacturing process, there is a high likelihood of endotoxin contamination. This endotoxin contamination will not be remedied with post process sterilization. Water used in medical device manufacture should be tested for endotoxin, as well as the medical device itself.

The device is typically extracted in endotoxin free water at 37°C for one hour, and then assayed for endotoxin according to USP <85>.

USP 85 Endotoxin Testing

Why FOCUS for USP <85> Endotoxin Testing?

FOCUS Laboratories can test drug products and medical devices for the presence of Endotoxin through USP <85> tests. Our methods and validations are done effectively and thoroughly. And we are proud to produce accurate, on time with a possible turnaround time of one day and cost-effective results.

Call us at 610-866-7272 for a free quote.

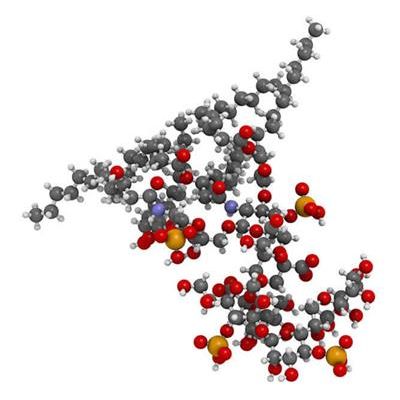

A drug product or medical device may be sterile, but it can still contain endotoxin that will make a patient sick. Endotoxin is a complex lipopolysaccharide (LPS) found in the outer cell membrane of gram-negative bacteria, typically water borne. Sterilizing by autoclave or other means may kill these bacteria but leave the endotoxin behind. Endotoxin is measured in Endotoxin Units per milliliter (EU/mL). One EU/mL equals approximately 0.1 to 0.2 ng/mL.

Endotoxin is quantified in drug products or medical devices using Limulus Ameobocyte Lysate (LAL) derived from the blood of horseshoe crabs. The presence of endotoxin mixed with LAL causes LAL to clot. When LAL is standardized, quantification is possible.

Kinetic assays are also available, that measure increase in reactant turbidity. These endotoxin tests require less dilutions and are preferred for quantification.

Test Requirements:

Only a few mL or gm of test product are required, and TAT is possible in 1 day if necessary.