Enviropol Engineers Pvt.Ltd.

- Home

- Companies

- Enviropol Engineers Pvt.Ltd.

- Products

- Enviropol - Wet Scrubber

Enviropol - Wet Scrubber

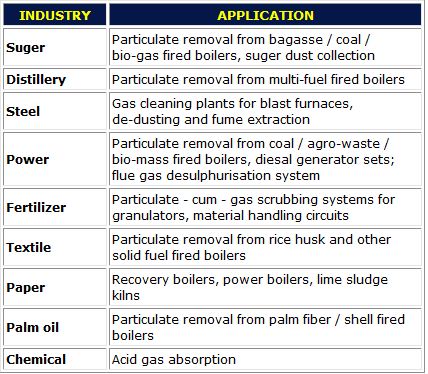

Enviropol Engineers is a leading wet scrubber manufacturer, supplier and exporter from India. We are supplying high-quality wet scrubbers and venturi scrubbers around the world at the most competitive prices. Wet scrubbers are the most common FGD method currently in use; they include a variety of processes and involve the use of many sorbents and are manufactured by a large number of companies. The sorbents used by wet scrubbers include calcium-, magnesium-, potassium-, or sodium-based sorbents, ammonia, or seawater. Currently, no commercial potassium-based scrubbers are in use, and only a limited number of ammonia or seawater systems are in use or being demonstrated. Our Manufacturing Range Fluidized Bed Nye Tray Fixed Vane Scrubber High Energy Venturi Scrubber Multi-Jet Spray Tower Packed Bed Tower Dynamic Scrubber Wet Cyclones Wet Scrubber Internals Wet Scrubber for CrematoriumMost popular related searches

wet scrubber

slurry dewatering system

high-energy venturi scrubber

slurry dewatering

dewatering system

venturi scrubber

solid-liquid separator

make-up water

solid-liquid separation

air pollution control

When the micron sized particulate matter pass through the fluidized bed of water, they are entrapped in the bubbles due to differential density and get precipitated in scrubbing liquid.

Clean gas swirls upward to outlet through double stage mist eliminators. Liquid with entrapped particles drains via bottom cone for solid-liquid separation through Mechanized Slurry Dewatering System.

- Nearing 100% scrubbing efficiency

- Pressure drop - as low as 50 mmwc

- Low make-up water requirement

- No moving parts and nozzles

- Zero water carry-over

- Complete Automation

- Compact design

- Tolerate very high dust loading.

- Two tier separation-dry and wet.

- Inherent quality to reduce CO2 and other gaseous pollutants.

- Low gas-liquid ratio- reduced load on slurry dewatering system.

- Can be designed to operate on treated spent wash.

- Easily expandable to meet more stringent norms in future.

- No periodic cleaning required.

- It has over 99 % efficiency at 50 mmwc presuure drop as against minimum 250 mm wc required in Venturi design.

- Much longer time available for gas-water intermixing due to low gas velocity & positive water layer of 30-50 mm thick as against very thin spray water curtain in venturi.

- Consistency in emission result due to almost no space for gas to go un-scrubbed as against most of the other designs having fair chances of some stream of gas escaping without touching thin water curtain formed by spay nozzles due to cavities.

- FBNT is easier to up-grade to face more stringent norms in future just by adding another stage of Tray with in the same vessel contrary to venturi design where the complete venturi section need re-designing.

- Best suited for all type of bio-mass applications as compared to other dry/wet systems such as ESP and venturi scrubbers.

- Carry-over of partially burnt particles and high resitivity of fly ash from bio-mass fired boilers make ESP vulnerable for fire hazards and less efficient as compared to FBNT where the particles are quenched in water & does not pose such threats.

- More eco-friendly disposal of ash in the form of wet cakes through Mechanized Slurry Dewatering System as against dry ash from ESP.

- 100 % re-circulation of water through Enviropol-mechanized slurry dewatering system ensure zero water discharge from the system.