ERG - Water Regenerable Activated Carbon Filters

ERG’s Water Regenerable Activated Carbon Filters are specially designed for Sewage Odour Control in the Middle East. All our systems come with a performance guarantee backed by more than 30 years of experience successfully treating municipal odours around the world.

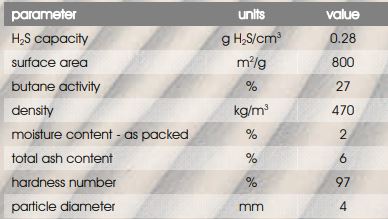

The water regenerable carbon is a high activity, non-impregnated activated carbon designed especially for specific removal of H2S and mercaptans in sewage treatment applications.

Each water regenerable carbon filter is filled with catalytically enhanced, coal-based activated carbon pellets or granules. This water regenerable carbon is a unique product that it is made without the use of chemical impregnation to the surface of the carbon.

The water regenerable carbon removes H2S by using catalytic activity rather than impregnated chemicals. This eliminates the potential heat build-up caused by the presence of impregnates.

H2S removal capacity can be restored simply by washing with water in place of the hazardous chemicals used with impregnated carbon.

ERG offers a competitively priced range of regenerable carbon filters for treatment of sewage odours from:

- pumping and lift stations

- inlet works and primary treatment

- filter press rooms

- sludge tanks and sludge treatment areas

- complete sewage treatment works

Key benefits of ERG`s water regenerate carbon fitters

- High removal efficiency of HjS. mercaptans, and other odours

- Outlet H^ concentrations

- Odour polish to < 200-500 ou^m3

- Filters to treat 200 to > 100.000 m3/hr air

- Low pressure drop < 500 Pa

- Regeneration period and bed life designed to suit requirements

- Ideal for inclusion as polishing filter

- Designed for high humidity operation

- Vessels supplied in FVC/GRP or GRP

- Integrated systems with ductwork, fans and controls

After breakthrough of H2S is detected, carbon media can be regenerated ins/tu by simple water washing. The water washing effectively reduces HjS to a dilute sulphuric acid stream. The quantity of water required is typically 3 to 5 times the volume of carbon in the filter. Wash frequencies depend on the filter size and the inlet H?S loading -typically 3 to 12 months are designed for.

Operating Cost

The carbon is suitable for 5 to 8 regeneration cycles before carbon replacement is required. This compares with a traditional caustic impregnated carbon filter which would need to be replaced after first breakthrough.

The operating costs of the system using water regenerate carbon are 75% lower than odour control system using conventional impregnated carbon.