- Home

- Companies

- ESCO International (EI)

- Products

- ESCO - Model Catadox Pilot - Advanced ...

ESCO - Model Catadox Pilot -Advanced Oxidation Pilot Plants for Wastewater & Gas Treatment

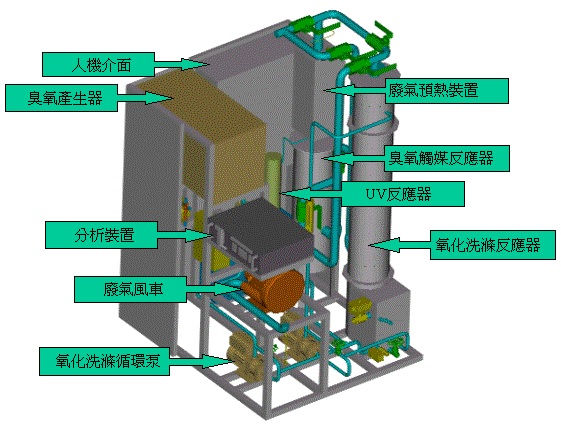

ESCO International has developed and tested a new advanced oxidation pilot plant, CATADOX. The process combines treatment by ozone, UV, hydrogen peroxide and proprietary catalyst to enable the industry to meet the evertightening environmental standards for wastewaters & gases. The CATADOX, performs excellently in challenging applications such as micropollutant oxidation, non-biodegradable COD removal, TOC reduction, VOCs abatement, toxicity reduction, colour & odour removal. Advanced oxidation processes are the most reliable means of meeting the new standards. They offer substantial capital and operating cost savings compared with other conventional treatment processes.

The CATADOX system is specifically designed to efficiently treat a wide range of refractory organic pollutants, COD and TOC in water & gas effluents.

The process combines ozone, UV, H2O2 and proprietary catalyst. By combining two oxidants, the oxidation potential will increase and the treatment can be more successful than a single oxidant.

The CATADOX system involves three main components for the effective generation & optimum use of hydroxyl free radicals for the enhanced oxidation of pollutants, COD and TOC:

- UV-radiation,

- ozone & hydrogen peroxide,

- a proprietary catalyst.

The CATADOX process provides unique benefits:

- Significant cut down in ozone demand, hence smaller ozone generator

- Important reduction in oxygen and dry air requirements, hence lower power consumption

- Major reduction in cooling water capacity

- Reduction in plant size

- Higher flexibility in oxidants dosing vs incoming TOC or COD

- Better process performance and reliability

- Much lower overall power consumption

- no oxidant residual problems

- optimal combination of ozone , H2O2, UV available depending on water quality and requirements before discharge or reuse

- lower ozone, H2O2 and UV power requirements when compared to conventional H2O2/UV, O3/UV and O3/H2O2 AOP processes.

- Wastewater feed flow rate range: 1-7 m3/h

- Waste gas flow rate range: 0-50 m3/min

- Ozone generation capacity: 0-240 g/h

- Ozone concentration range: 0 -150 ppm

- Hydrogen peroxide concentration range: 0-70 ppm

- UV oxidation power range: 0-1500 W

- Oxidation contact chamber: 5 – 20 min

Services Requirements:

- Mains power 400V, 50-60HZ, 3Phase

- Cooling water : by customer

- Oxygen (integrated)

- Hydrogen peroxide (integrated)

- pH adjustment (integrated)

- On-site destruction treatment technology

- No phase transfer required, thereby eliminating secondary handling

- Efficient for a wide range of contaminants types and concentrations including IPA, TMAH, NMP, DMSO, Glycols, VOCs, PAHs, PCBs, Alcohols, Ethers, Urea, TOC & COD and others..

- Low maintenance and operating requirements

- Quiet and unobtrusive equipment

- Safe and environmentally friendly

- combination of advanced oxidation process (AOP) including ozone / UV / H2O2/Catalyst

- designed to mimic full scale plant operation

- mobile & self-contained plant

- high ozone dissolution and mass transfer performance

- pH correction of influent

- ozone generator

- integrated oxygen generating system

- vent ozone destruction

- dissolved ozone monitoring device

- allows experimentation with different loadings

- demonstrates effluent treatability

- enable you to conduct trials on your own site with the actual effluent to be treated

- establishes precise design parameters

- accurately predicts capital & operating costs

Recommendations:

If you are thinking of installing an on-site advanced oxidation plant for wastewater reclaim, it is sometimes necessary to carry out pilot studies to ensure that the correct design criteria are used for the full scale plant. ESCO recommends that the pilot plant evaluation work is carried out for at least a week.

- allows experimentation with different loadings

- demonstrates effluent treatability

- enable you to conduct trials on your own site with the actual effluent to be treated

- establishes precise design parameters

- accurately predicts capital & operating costs

Recommendations:

If you are thinking of installing an on-site advanced oxidation plant for wastewater reclaim, it is sometimes necessary to carry out pilot studies to ensure that the correct design criteria are used for the full scale plant. ESCO recommends that the pilot plant evaluation work is carried out for at least a week.