- Home

- Companies

- Efficiency Scientific Instrument Co., ...

- Products

- ESI - Model H500 - Handheld XRF Metal ...

ESI - Model H500 -Handheld XRF Metal Analyzer

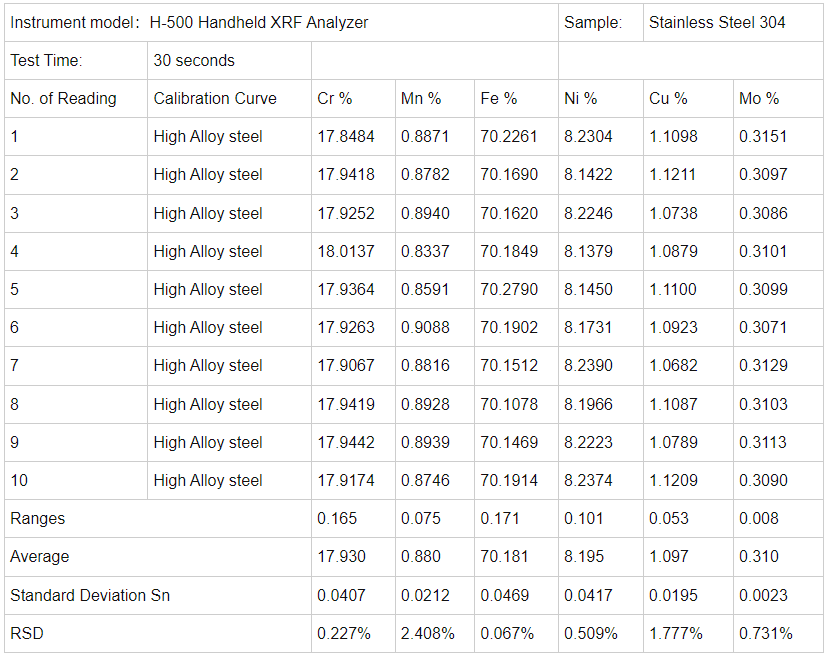

H500 provides highly precise measurements from trace to minor to major concentrations of relevant elements. H500-Handheld XRF Alloy Metal Analyzer Positive Material Identification (PMI) with a ESI PMI Gun. The requirement for positive material identification (PMI) in alloys used throughout the physical plant is more critical than ever. Simply relying on spot testing of parts and sub-assemblies is too risky and unacceptable; in fact, best practices today include 100% PMI testing of all critical materials. While that may seem like a formidable challenge, it’s now a surprisingly easy task thanks to technology that can literally fit in the palm of your hand with the H-500 handheld xrf analyzer.

Simply the Best

H500 provides highly precise measurements from trace to minor to major concentrations of relevant elements. That kind of accuracy - exceptional for any portable elemental analyzer - enables it to reach remarkable performance levels.

Now there’s a proven solution that can provide laboratory-class, reliable, rapid results on site

Families of alloys that can be accurately identified and analyzed include:

- Stainless steels

- Cr-Mo steels including

- V stabilized versions

- Low alloy steel

- Tool steels

- Nickel alloys

- Copper alloys

- Titanium alloys

- Aluminum alloys

- Exotics, such as zirconium and tantalum alloys

Achieve all this and more with handheld XRF – the nondestructive testing method that leaves samples undamaged in any way

- Simultaneous elemental analysis.

- One calibration – for multiple matrices over a wide dynamic range.

- Various sample types including liquids, solids, pastes, powders, films, and pellets.

- No purge or combustion gases required.

- User defined measurement times (20 - 200 seconds.)

- Multiple Calibration Curve capability with easy storage and retrieval for matrix matching

- Designed for Easy Operation

- Competitive Cost

- Laboratory quality with fast field results

- Analytical Method: Energy Dispersive X-ray fluorescence

- PDA with touch screen: CPU: 1G, System memory: 1G, standard 4G mass storage data, extended stored maximum support up to 32G, Large LCD touch screen, 1820x720 resolution

- Intelligent Analysis: Automatic select test mode based on sample matrix

- Excitation Source: 50KV/200µA – Ag/Rh end window integrated miniature X-ray tube and high voltage power supply

- Collimator & Filter: Multiple Collimator and filters with automatic switching functions

- Detector: Silicon Drift Detector (SDD)

- Detector Resolution: Up to 125eV

- Sample States: Solids, liquids, powders

- Elemental Range: Atomic numbers between 12 (Mg) and 92 (U)

- Detection Limit: 1 – 500ppm, depending on element and sample matrix

- Analysis Time: 3-60 seconds

- Simultaneous Analysis: Displays up to 40 elements at a time

- Display Range: ppm – 99.99%

- Sample View System: High-resolution integrated camera

- Connectivity: USB, GPS, Wi-Fi or Bluetooth

- Safety: Automatic shutdown of X-ray tube, Pb-lined instrument frame,radiation levels within international safety standards

- Power Supply: Rechargeable Li battery, standard 9000mAh, provides up to 12 hours operation on a single charge; 110/220V universal adapter for charging

- Temperature: -20ºC to +50ºC

- Humidity: ≤90%

- Weight: 1.75 kg

XRF analysis with Fundamental Parameters (FP) converts elemental peak intensities to elemental concentrations and/or film thicknesses. The analysis can be performed standard-less, where all variables are based upon theoretical equations, the fundamental parameter database, and precise modeling of the detector, X-ray tube, and geometry. Standard-less mode is possible for simple bulk or single-layer thin-film samples when the film thickness is known. The FP analysis can also be performed with standards. This is achieved through a calibration step where the XRF response function for each element is measured using a known standard of some kind. A with-standards analysis provides the most accurate results.

X-ray fluorescence (XRF) spectrometer is used in the determination of elements composition present in solid, powders and liquid samples. XRF detectors operate by bombarding a sample with high-energy X-rays which ionize the atoms and cause electrons from within the inner orbital shells of the atoms to be ejected into outer shells. This causes instability within the atom such that an electron from an outer orbital shell falls into the inner orbital to take the place of the ionized electron. As an electron drops from an outer, high-energy orbital into an inner, low-energy orbital, the difference in energy is released in the form of a photon. This released energy is characteristic of the electron orbitals and atoms present in the sample. A detector collects the emitted photons and categorizes them based on the energy level of the radiation; the relative intensity of each wavelength of characteristic radiation indicates the proportion of the elements in the sample.

We offers a full range of technical support to keep you up and running.

We develop, manufacture and distribute emission spectrometers for precise and quick element analysis of metals ,alloys and other materials. Our systems are optimized to guarantee reliable production control and material testing in all areas where the composition of materials constitutes a decisive quality criterion.

At ESI, user support starts when the spectrometer is commissioned on site at the customer’s premises by our highly skilled service engineers. Next to the provision of in-depth user instructions and training, the commissioning process includes comprehensive testing of the device functions together with the customer. If required, user-specific adjustments can also be made at this point. On request, we can also run preliminary acceptance tests at our premises.

Spare parts remain available for a minimum of 10 years following delivery and can be ordered by telephone, email or in writing from ESI or the respective representation abroad. Please use our contact form for email orders.

Our spectrometers can be modified on site at the customer’s premises to respond to changes in analytical tasking. Software upgrades, calibration extensions and installing customer-specific data are naturally also possible.

User training can be provided at the premises of ESI or the customer on request. Please contact our service team to schedule a date.