- Home

- Companies

- Synergy World Limited

- Products

- Evolution - Steam Technology

Evolution - Steam Technology

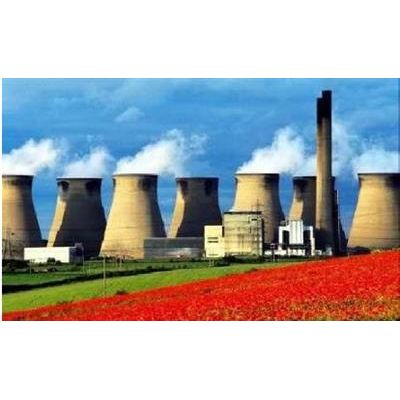

To a country’s development, energy means the lifeline and motive power. It does not only increase the competitive capacity of the product but also decrease production costs, inflation and environmental pollution to utilize energy effectively and reduce unnecessary waste.

In our country, the energy consumption in the industrial community accounts for over two-thirds of the total national energy consumption. Energy saving must be the easiest and most effective way to improve productivity and enhance competitiveness. However, from a long run, effects of energy conservation in the industrial community are not so obvious.

because of more talking and less doing.Although there are some successful examples, they are in the minority.If entering into the plant which adopts the steam, you may see smoke everywhere. Standing nearby many heating equipment, you may feel that it is so hot. Those are the obvious energy waste phenomena. As for most of manufacturers, if not considering to change the whole processing conditions but only focus on waste heat recovery, enhancement of heat preservation or pipeline improvement, it is convinced that it is not so difficult to do this with less investment and energy expenditure reduced up to 20%.

Any industry must have raw materials of reliable source and adequate supply to keep a foothold in its industry. For example, the construction industry may also need the brick, lime, steel frame and cement; the brewing industry requires grain; without wool, cotton or artificial yarn, textile industry can not conduct production; paper in the paper-making industry is made from the wood.

In fact, effective use of raw materials plays a crucial role in the success or failure of any production undertaking. Although the general manager and engineer in any industry may know that if 50% raw materials are wasted in the process of production, the product produced may have no competitiveness on the market. However, engineers of many production lines still neglect the most precious energy and let it wasted and such precious energyis steam.

In the times of high science and technology and microcomputer widely used, steam plays an extremely common role in the industry circle and is often forgotten. Take our daily life as example, the clothing we wear, food we eat, drinking we drink, iron and steel, tire and fuel used in the car, furniture, newspaper, drug, paint, chemicals, glass, plastics, power supply etc. are produced through using steam because steam owns the following properties:

High thermal contents;

Release heat energy in a certain temperature;

It is generated by water and generally, water has adequate supply in the industrial countries;

Plenty of heat energy can be recycled.

Promote the steam turbine to generate power and utilize for production.

Steam condensates into water, and then evaporates via heating, implementing the recycle use of water and steam.

The steam system in many plants generates a good deal of invisible waste due to imperfect design, device and use. It becomes the public concern to improve service efficiency of steam and reduce steam application amounts in the aspect of energy saving because steam is directly produced by burning of fuel oil (often refer to petroleum) and petroleum may be the most precious energy in the world which can be used up soon. Having full knowledge of steam and making the most of it can allow the plant to improve efficiency of equipment and reduce production costs. With fuel consumption reduced, the plant can decrease its energy expenditure and will naturally increase the energy utilization rate. Steam energy saving can not only benefit the nation but people.

Zero emission steam generation technology is the integrated water-saving technology of the industrial boiler and also the new boiler water treatment technology. The boiler is the source of the thermal power in the process of industrial production and human life, which plays a crucial role in the development of national economy and deserves the reputation of "heart of the industry". The working medium of the boiler is water and boiler water treatment is significant of ensuring safe and economic running of the boiler. As the heat exchange equipment, the boiler transmits energy produced by burning of the external power (coal, oil and natural gas) to the working medium to make water change to vapor. The bad water may contain plenty of detrimental impurity. If water enters into the boiler without any prior treatment, impurity in the water will form scale or water granulated slag in the boiler, which will greatly reduce capacity of heat transmission of the boiler. The boiler scale will cause damage to the boiler tube due to overheat, fuel consumption increase, output reduction, decrease of boiler`s service life or accidents, so it is extremely significant to treat water in the boiler.

Running features of the traditional industrial boiler:

Adopt the ion exchange equipment to soften raw water to prevent boiler scale.

In the feeding water treatment process of the boiler, over 90% domestic boiler plants adopt the ion exchange method. When raw water passes through sodium ion exchange resin bed, calcium ion and magnesium ion in water are exchanged with harmless ion on the resin in order to remove calcium ion and magnesium ion from raw water and reduce residual hardness below 0.05mol/L. As for water with higher alkalinity, alkali reduction treatment may be further required. While adopting the ion exchange method for water treatment, it is required to drain recycled waste fluid because recycled effluent brine can make fresh water salinization. In this process, the waste water drained out accounts for 5-15% of raw materials.

Adopt the thermal deaerator to deoxygenize in order to prevent oxygen corrosion of the boiler.

In the running course of the industrial boiler, dissolved solid matter and suspended solids in water increase due to high concentration of water. For ensuring quality of steam and safety of the boiler, necessary continuous blow-down and fixed blow-down should be conducted to the boiler, in which the discharge capacity accounts for about 5-10% of water supplement of the boiler.

In the steam application part, the traditional running way only focuses on utilization of heat energy but neglects recycling of medium containing energy. The steam changes to hot water after working and condensation and quality of such condensation water containing high calorific value is far better than softened water and close to pure water. However, while recycling condensation water, it will cause severe corrosion to steel pipeline and iron contents will have serious contamination to water. While taking condensation water without treatment as makeup water of the boiler, plenty of iron ions in water will generate second scale or subscale corrosion on the heat-transfer surface of the boiler so as to cause more serious damage and make recycling of steam condensation water more difficult. Previously, recycling of condensation water was not taken into consideration while designing and installing the system and steam device of the industrial boiler, so steam condensation water was drained to trench and wasted. Although some users recycle the condensation water as water feeding of the boiler, recycling pipelines of condensation water have been severely corroded because of lacking effective pipeline anti-corrosion measures and condensation water treatment technology. The iron ion contents in condensation water are high, which will directly influence safe running of the boiler. Currently, standard-reaching recycling rate of condensation water in the industrial boiler is less than 20%.

Zero emission steam generation technology of the industrial boiler

Zero emission steam generation technology is the water-saving technology of the industrial boiler. This technology adopts the chemical approach and design of comprehensive system handling to stop pollution in the source of steam generation and eliminate or reduce drainage of recycled effluent brine, waste water soluble salt, back washing water, flushing water, continuous blow-down water, fixed blow-down water and polluted condensation water: to restrain metal corrosion of recycling system pipeline of condensation water, eliminate pollution of iron ion to condensation water, make condensation water with high calorific value and high quality recycled to the boiler to serve as makeup water, greatly reduce fuel consumption of the boiler, decrease softened water consumption and steam production costs and improve water quality of the boiler. Along with water quality of the boiler enhanced, it can greatly reduce boiler blow-down and heat losses from blow-down and improve its efficiency to make it run more safely.

Zero emission steam generation technology makes the boiler steam generation system change from running under massive blow-down (open-loop) to closed cycle (close-loop) operation. It has changed the traditional mode that the boiler must run under massive blow-down, which is the major breakthrough of boiler water treatment technology.